Spot welding electrodes

Production and sale of electrodes for spot welders

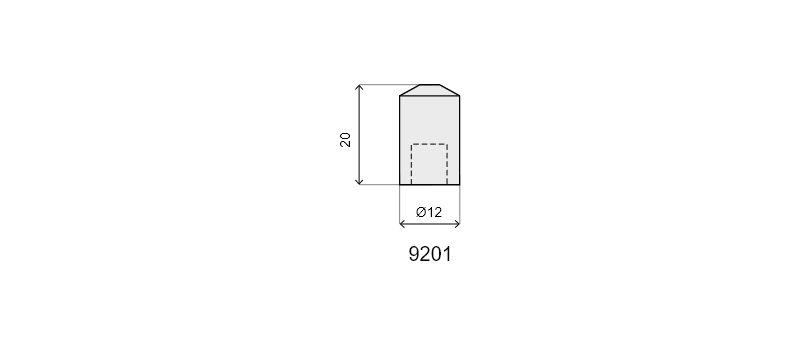

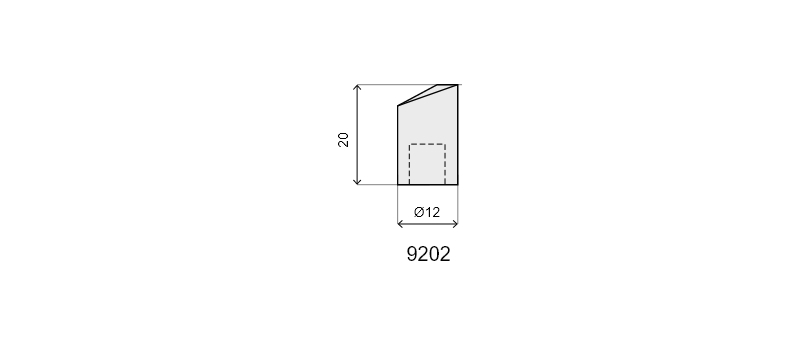

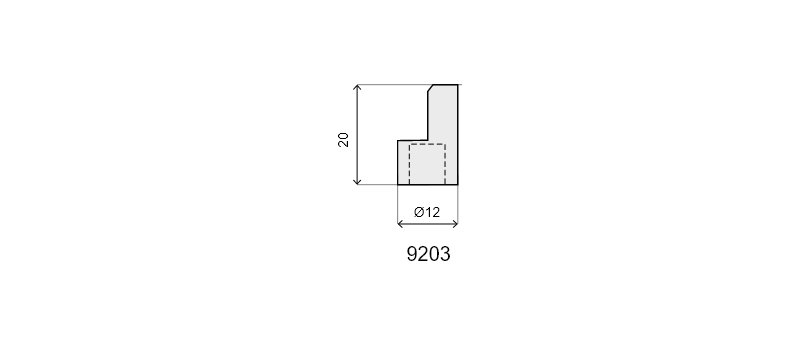

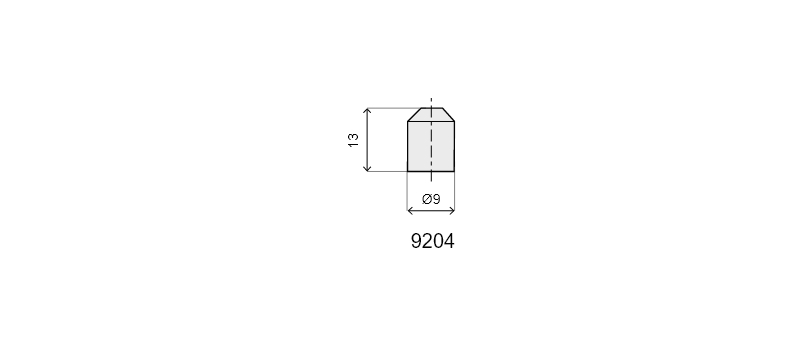

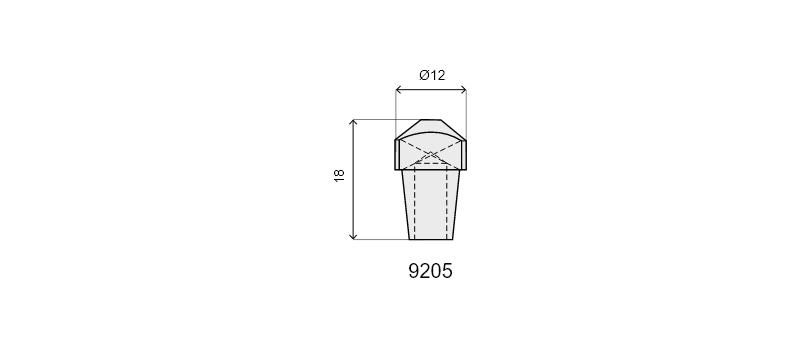

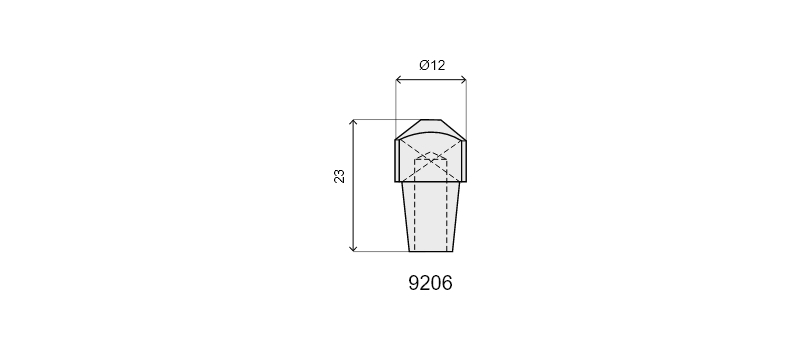

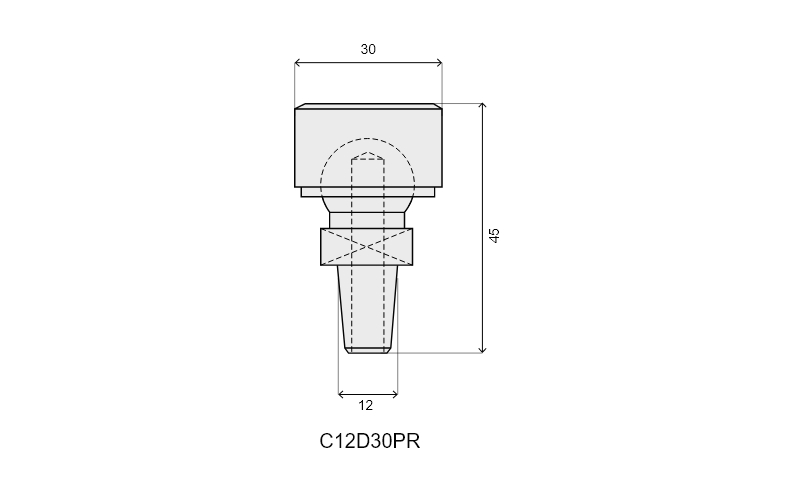

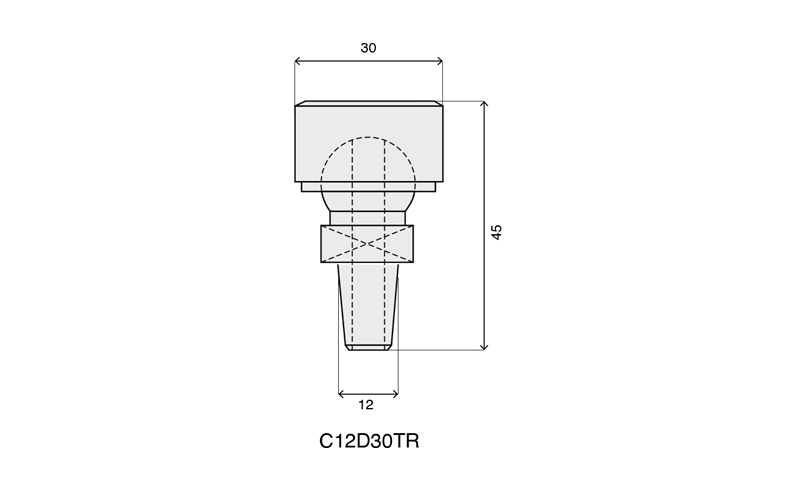

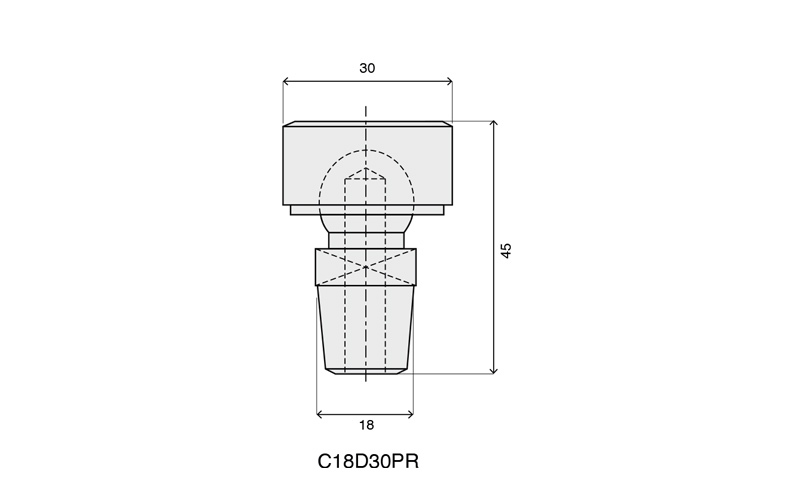

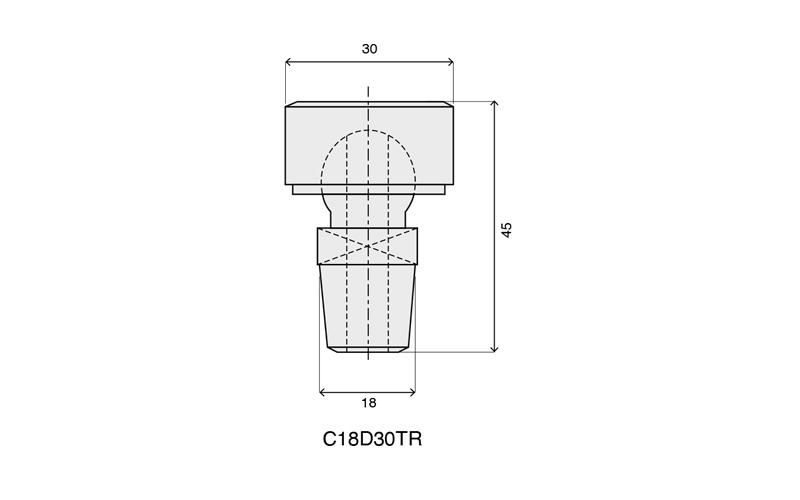

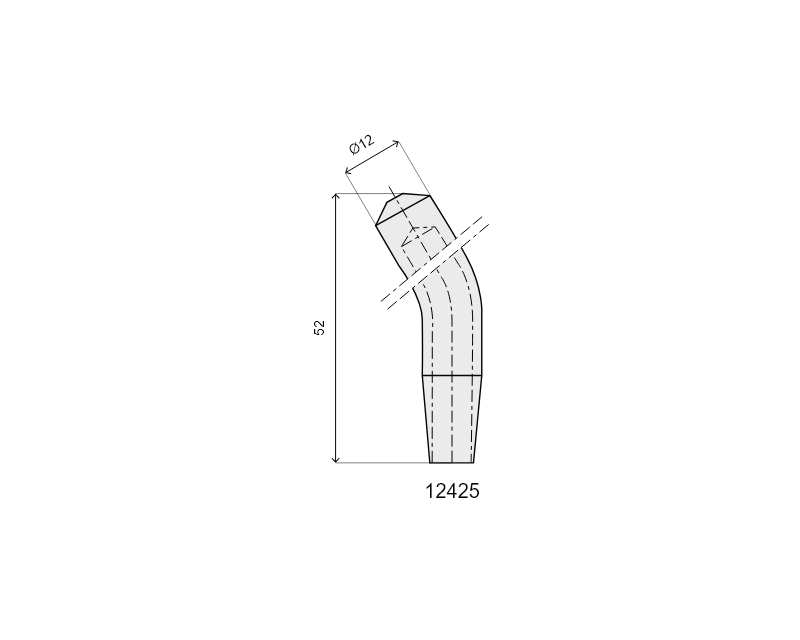

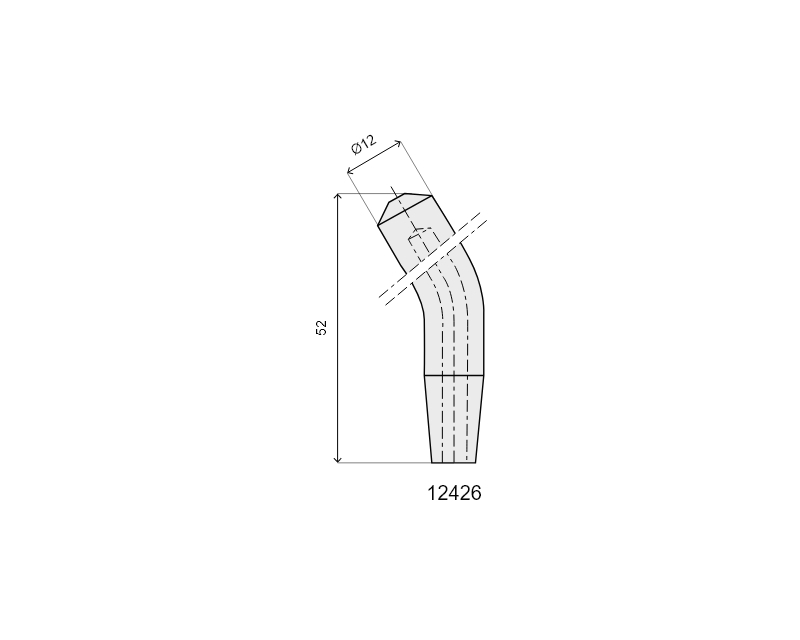

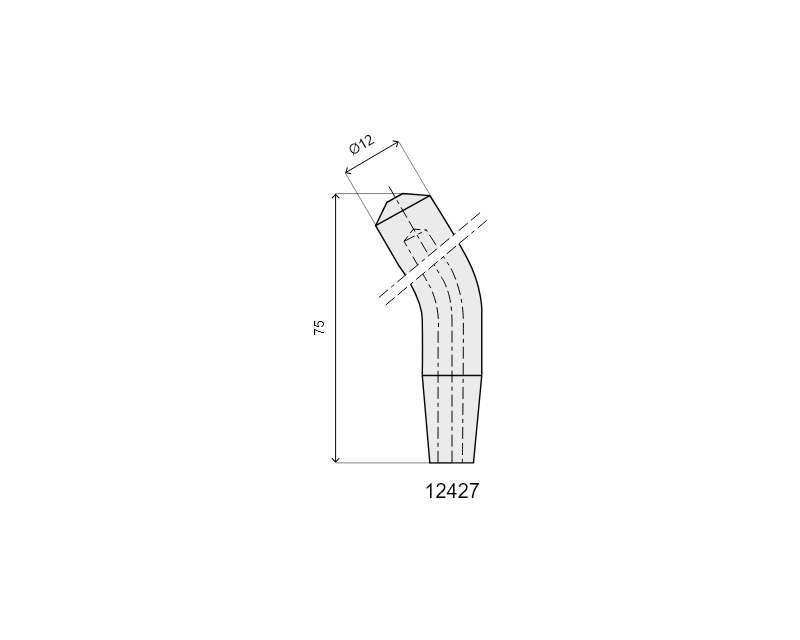

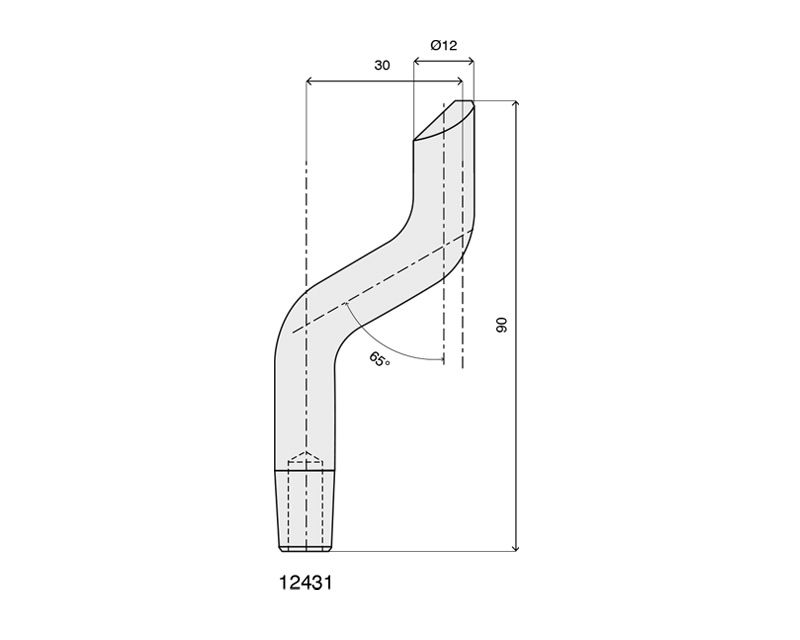

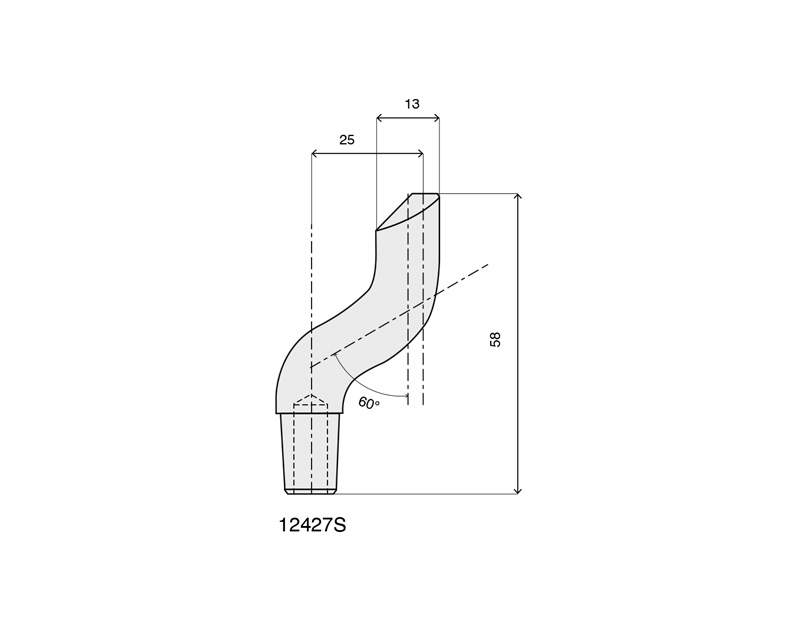

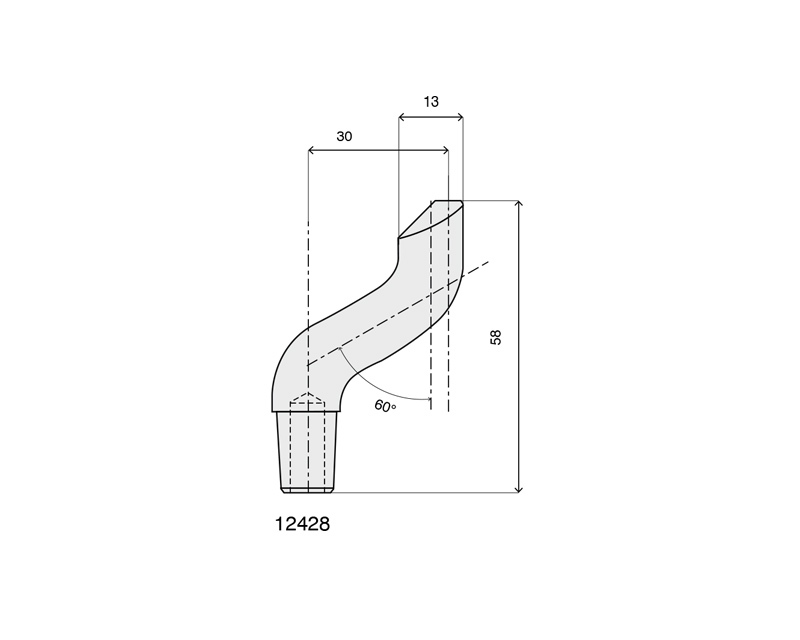

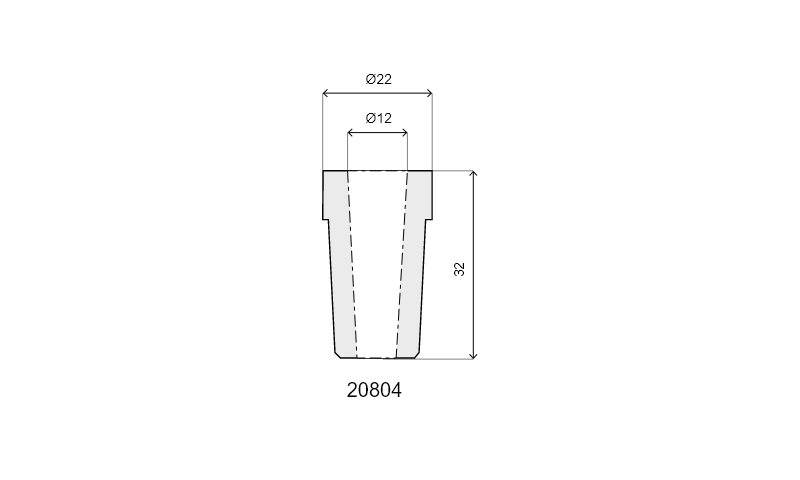

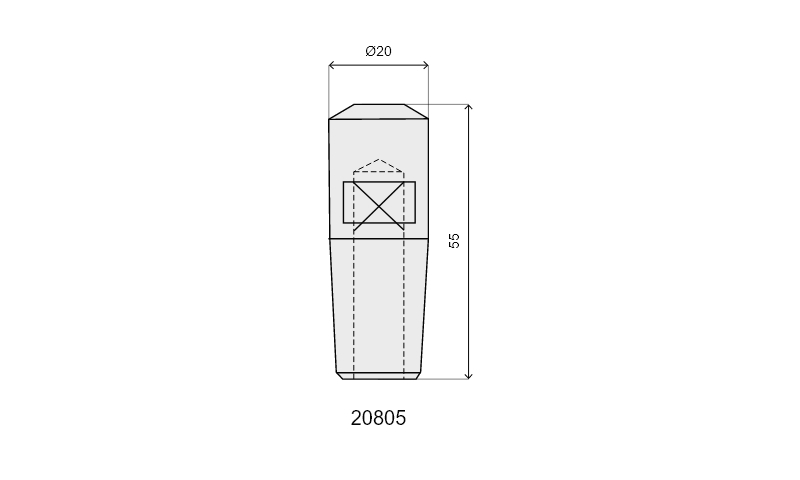

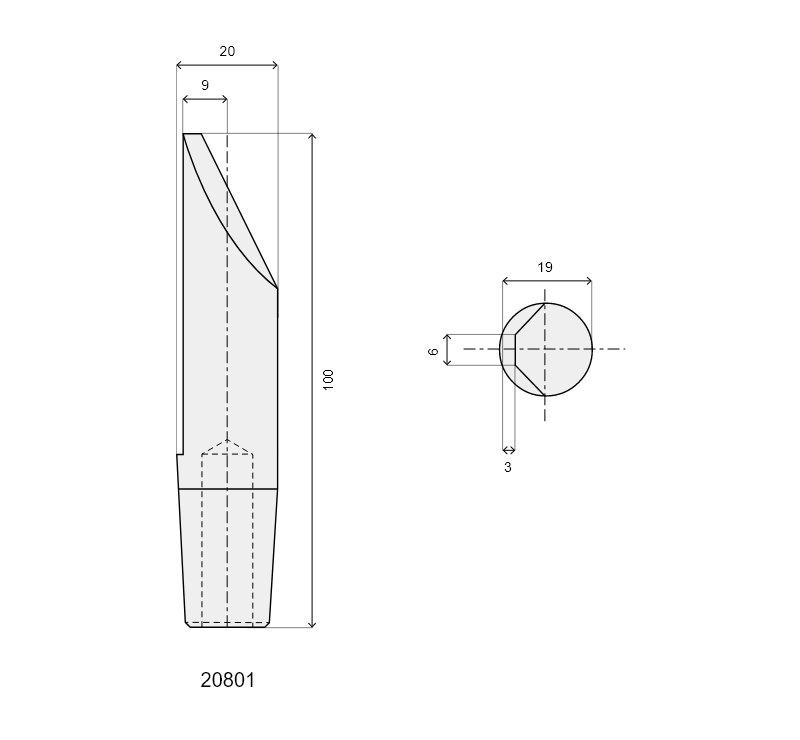

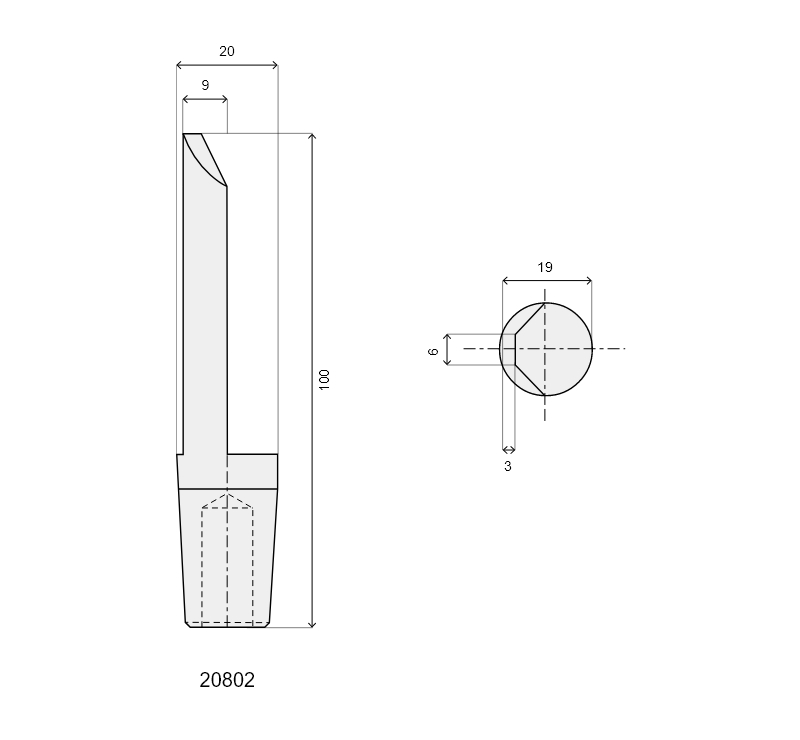

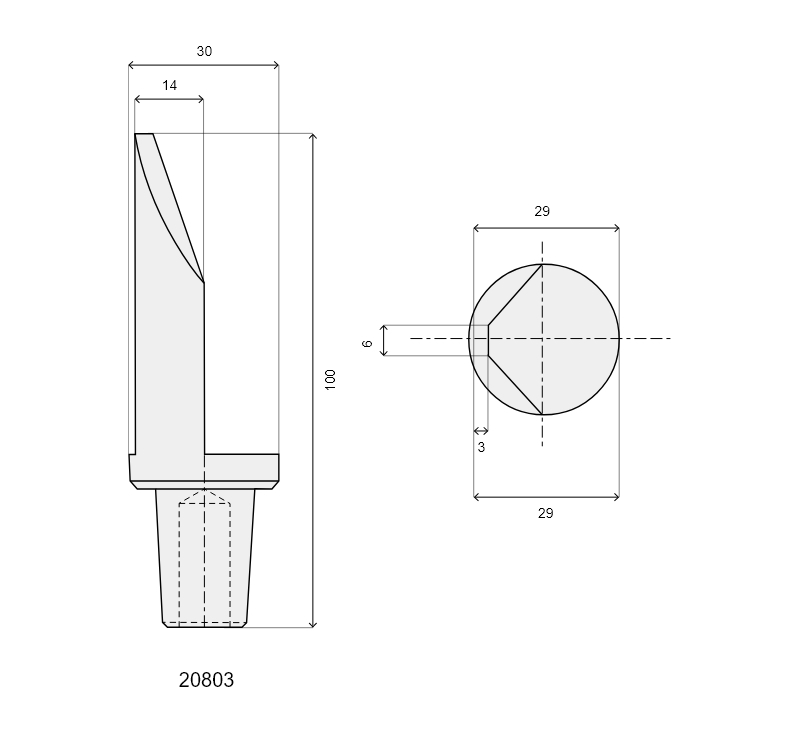

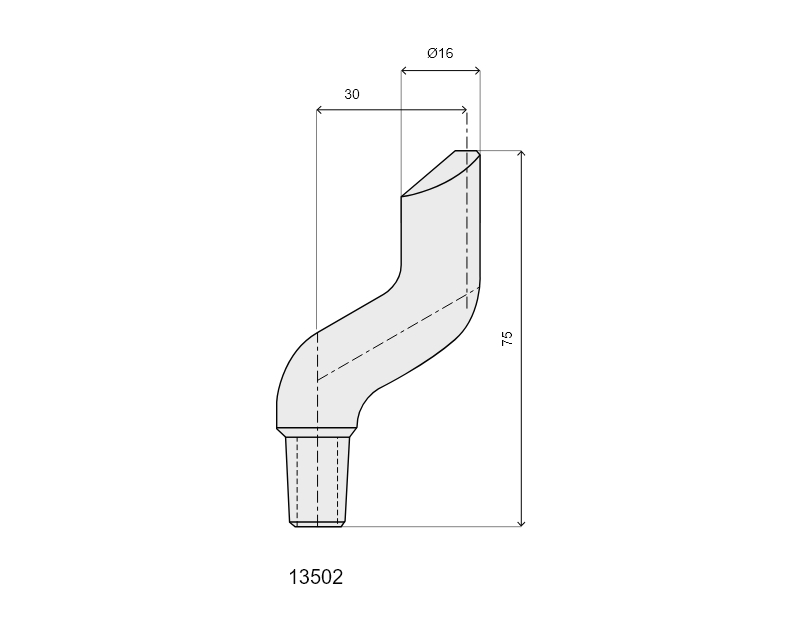

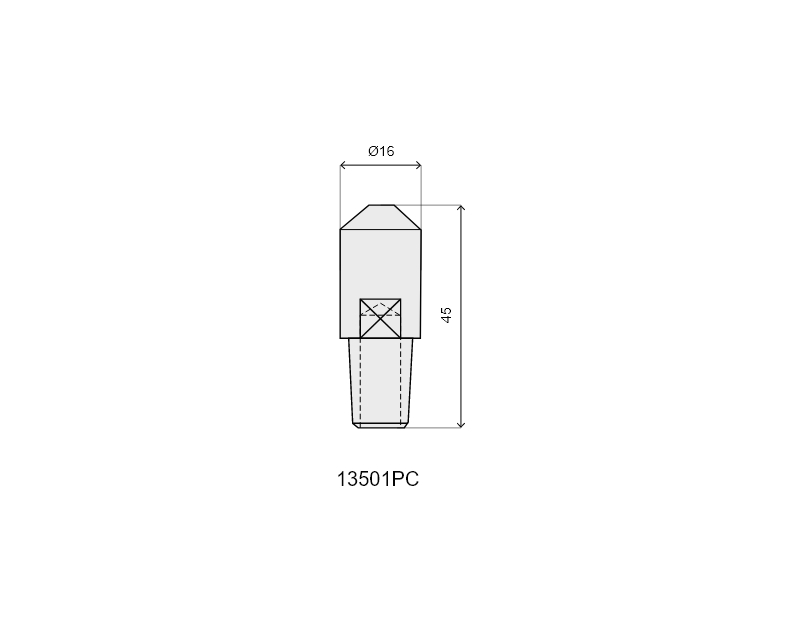

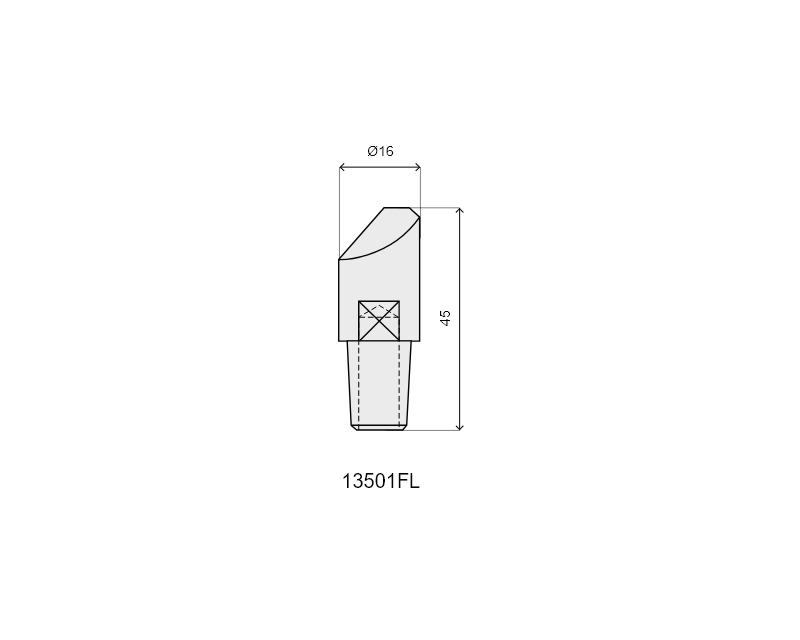

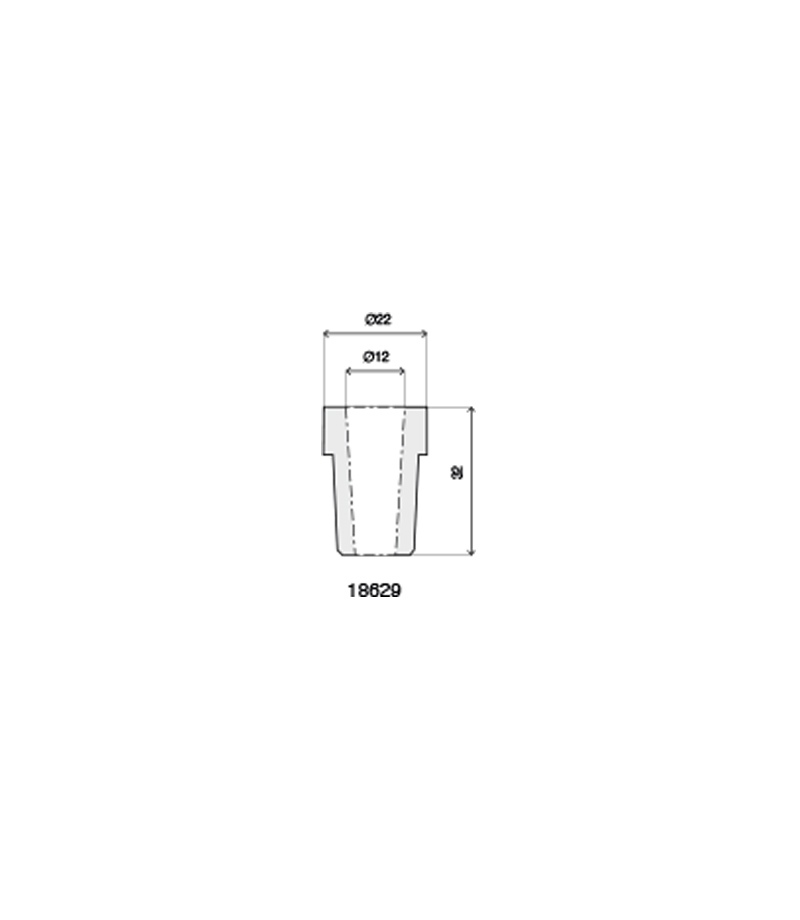

Tecsal specialises in the production of copper electrodes for spot welding machines, for all types of taper.

We produce the electrodes in-house, either from drawings or samples. In addition, we can design pointer tips for spot welders according to the customer’s specific welding requirements.

Our technicians are available for advice on the most suitable type of electrode for each requirement, e.g. the most suitable shape and alloy according to the type of shapes and materials to be probed, or advice on welding processes.

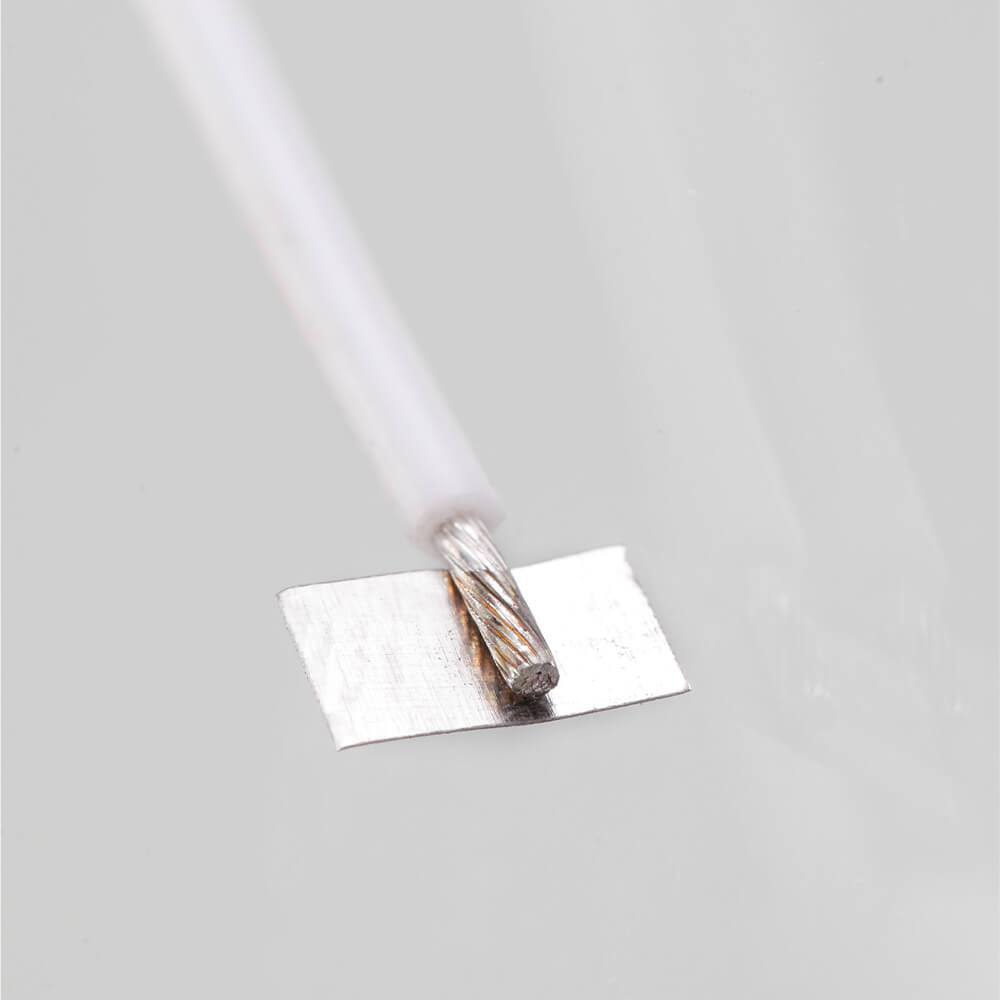

Our electrode tips are made of copper and copper alloys (CuCrZr, CuCoNiBe, CuW), with no limits on shapes and profiles. We work on the lathe and braze weld all alloys where necessary, which we know and purchase from trusted suppliers.

We use highly compatible software, such as SolidWorks for design and Autodesk FeatureCam for CNC machining.

Trust Tecsal as your welding partner

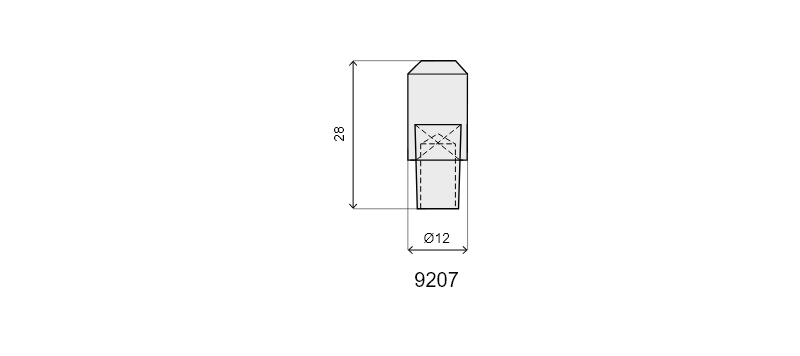

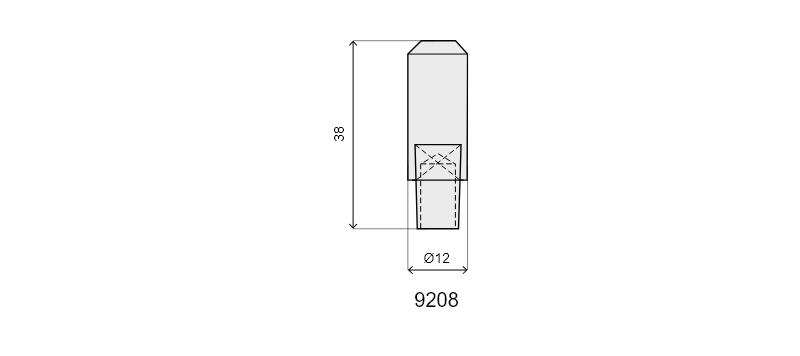

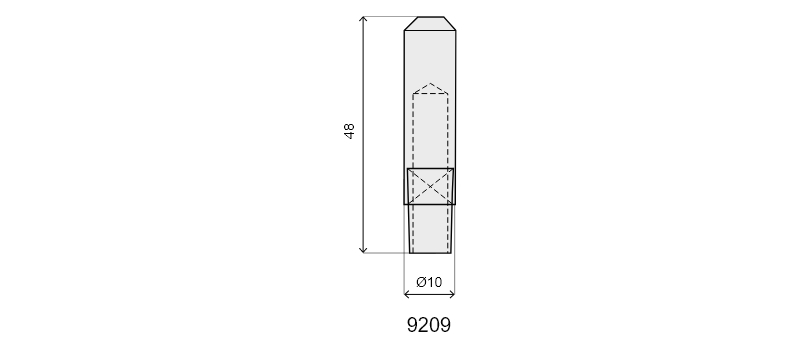

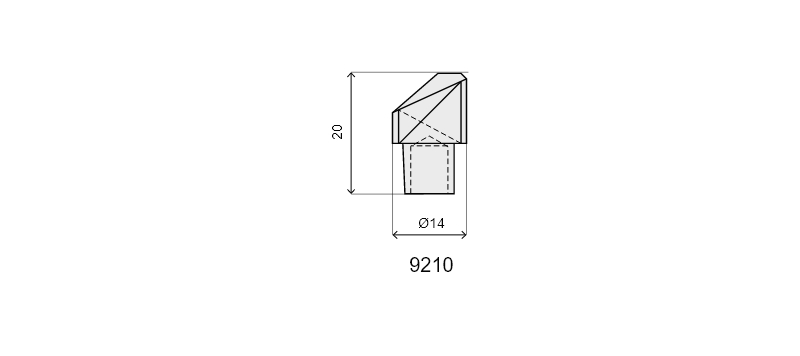

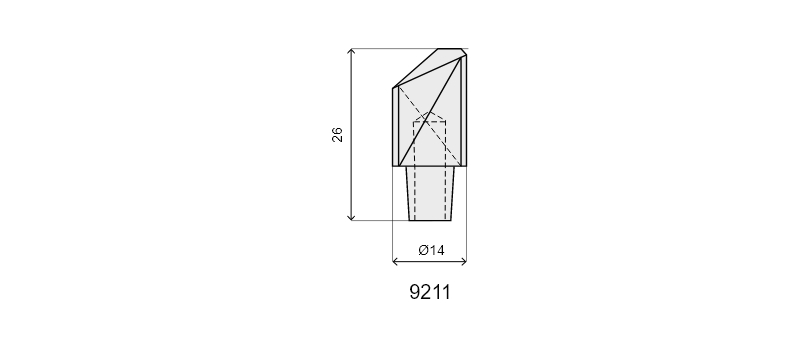

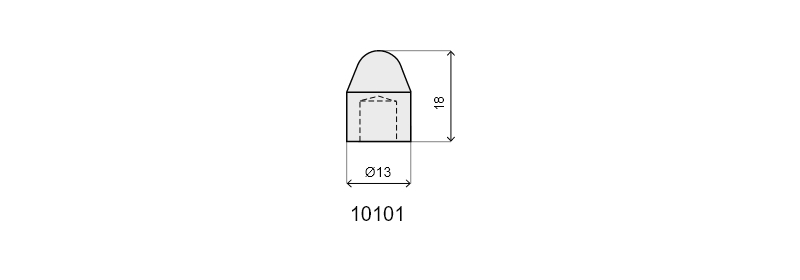

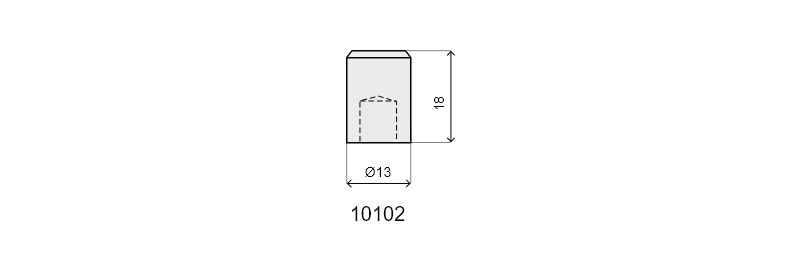

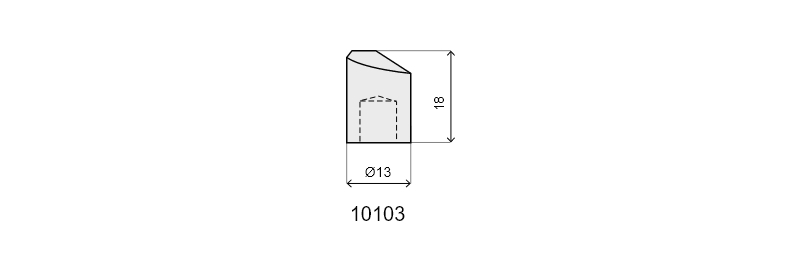

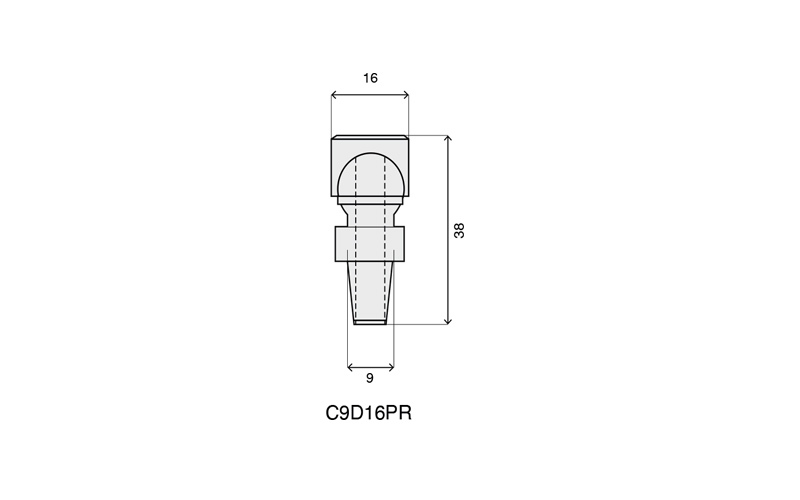

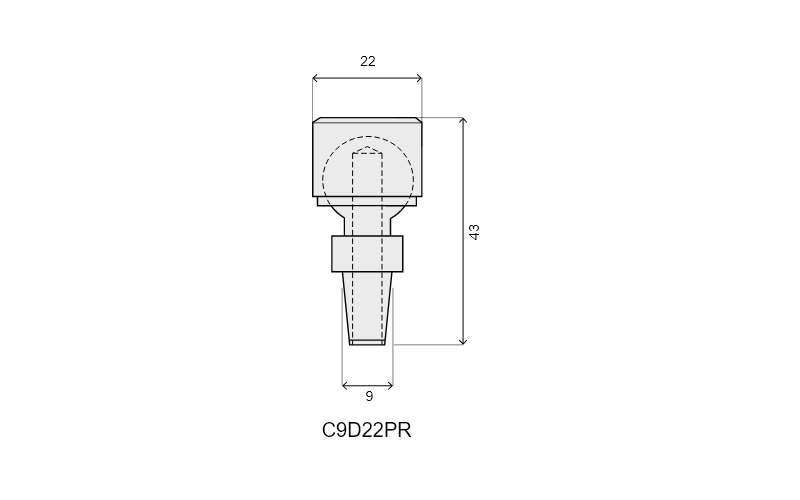

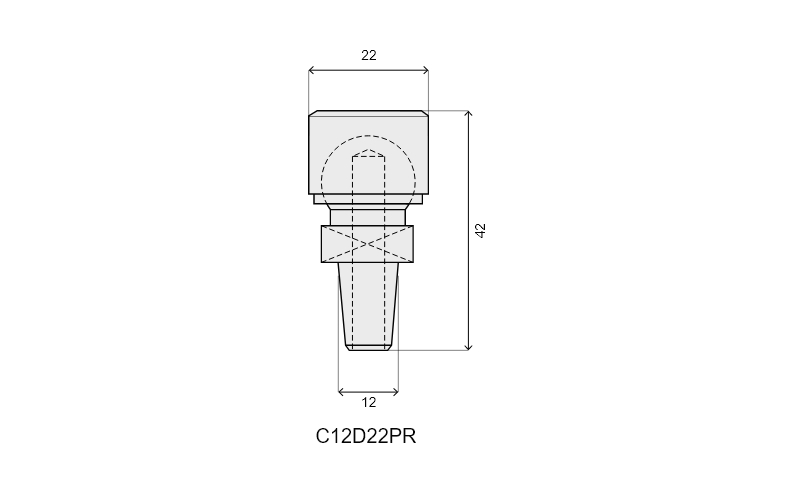

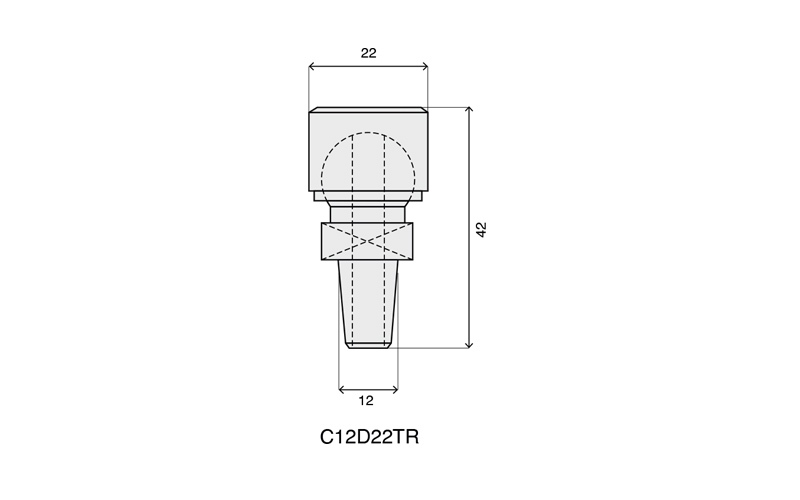

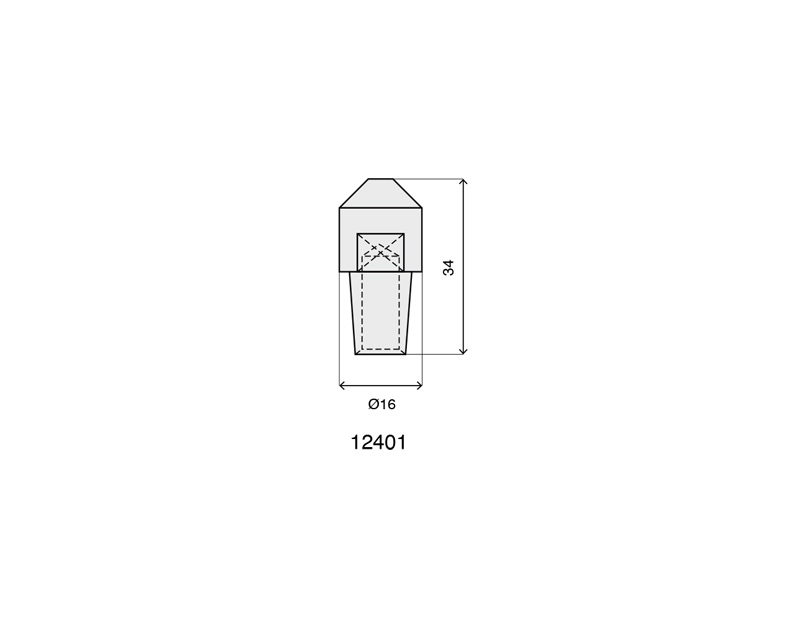

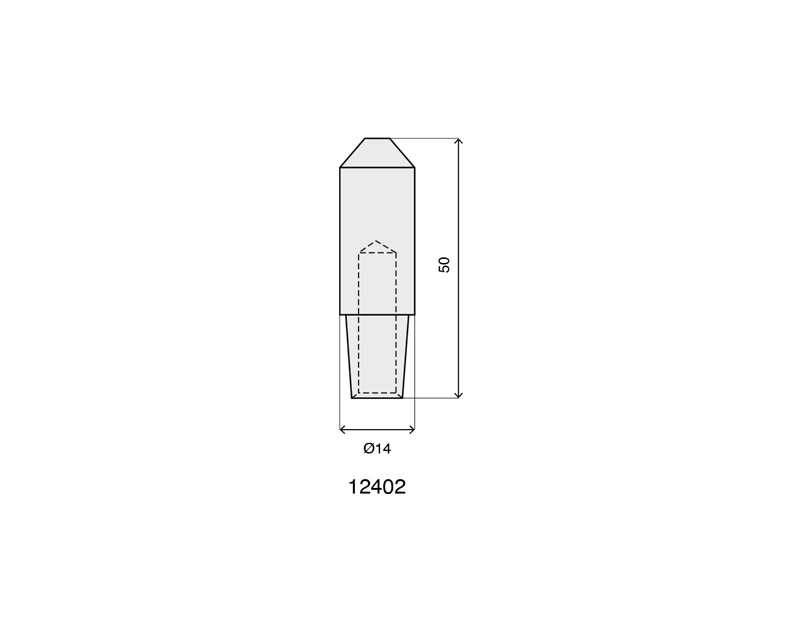

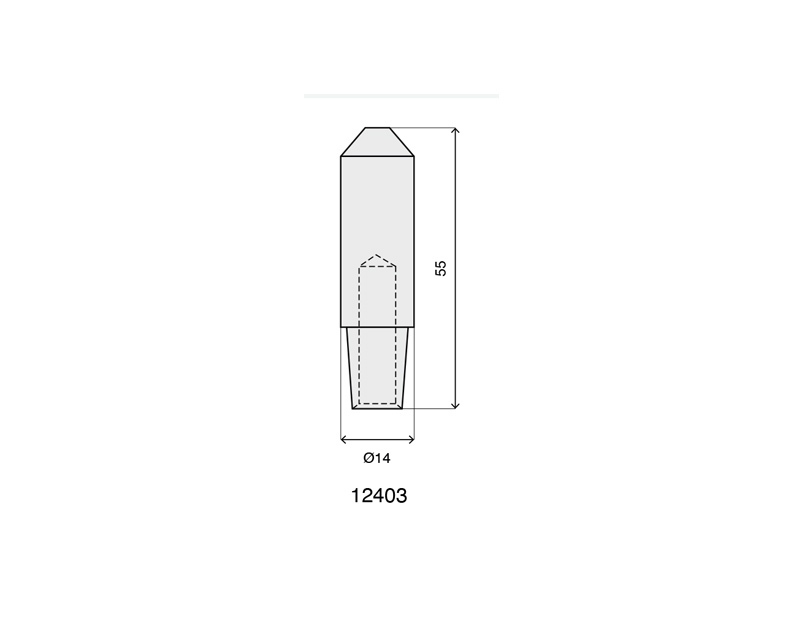

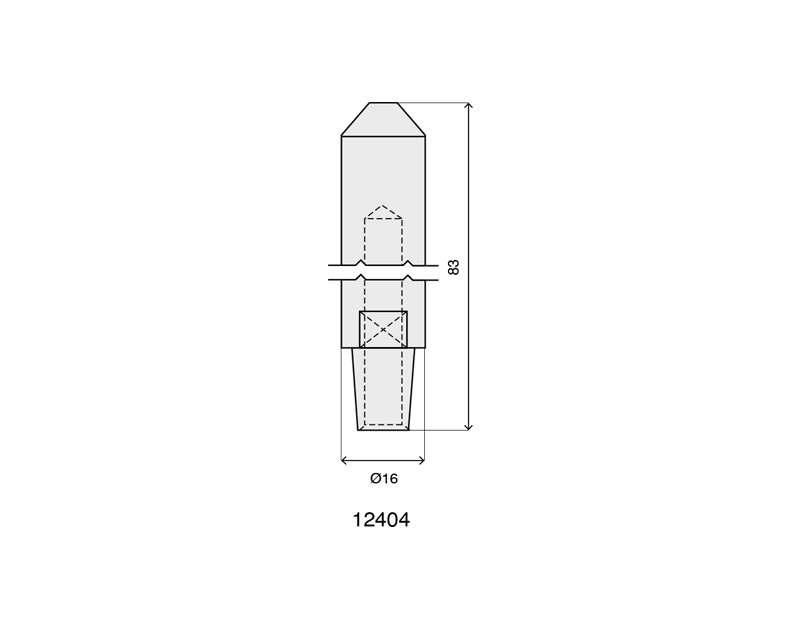

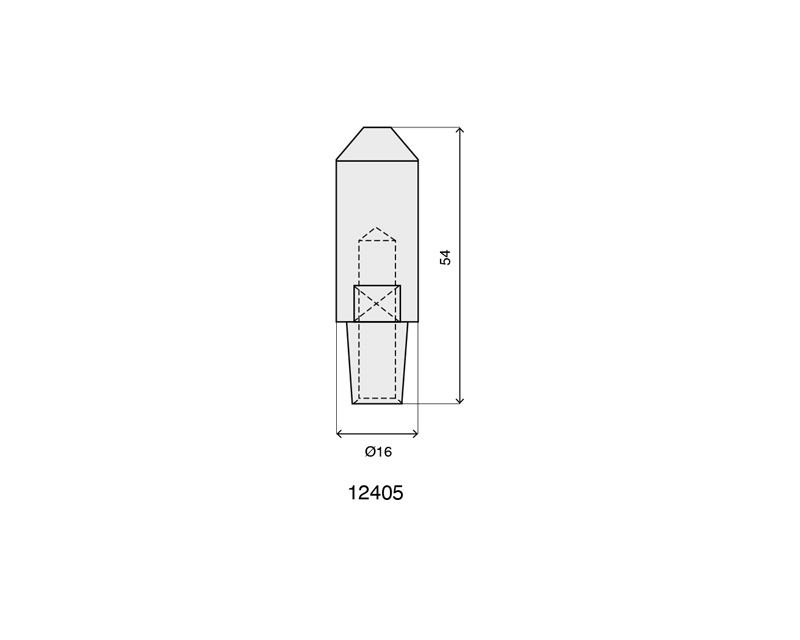

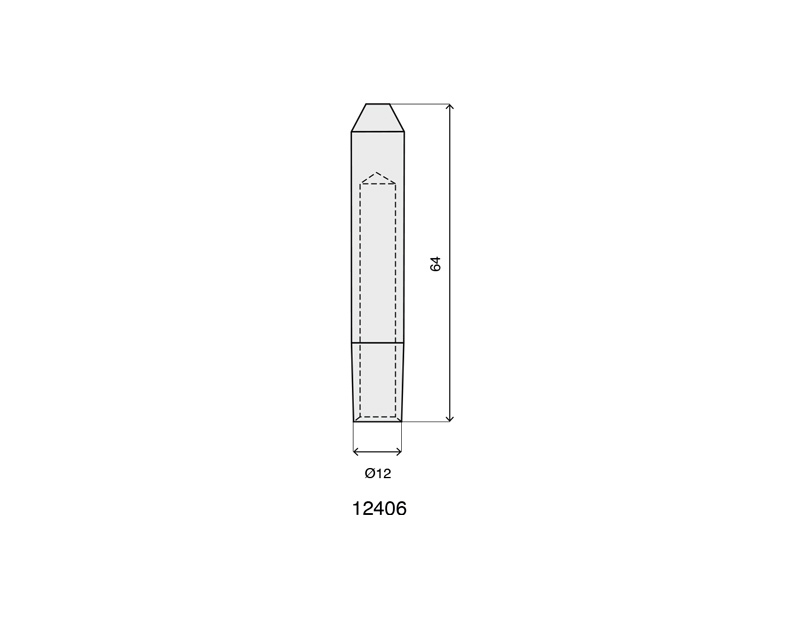

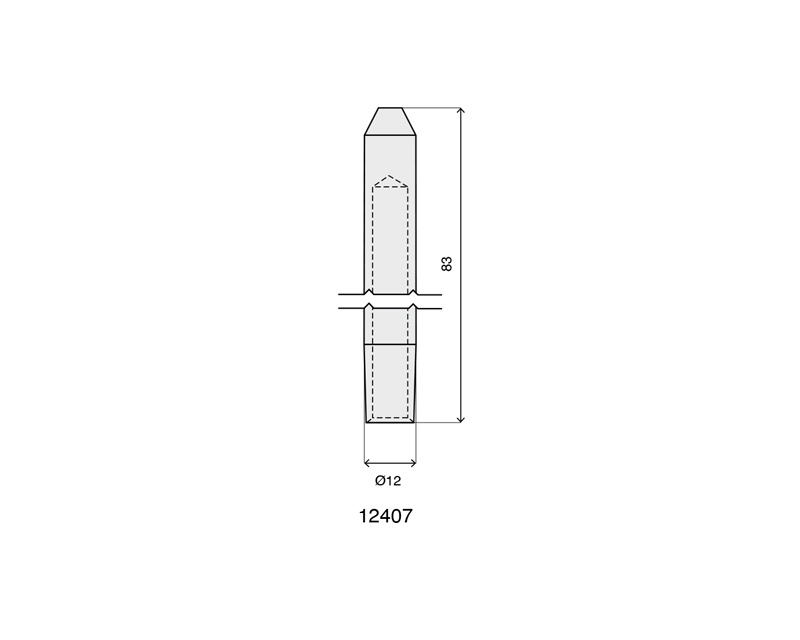

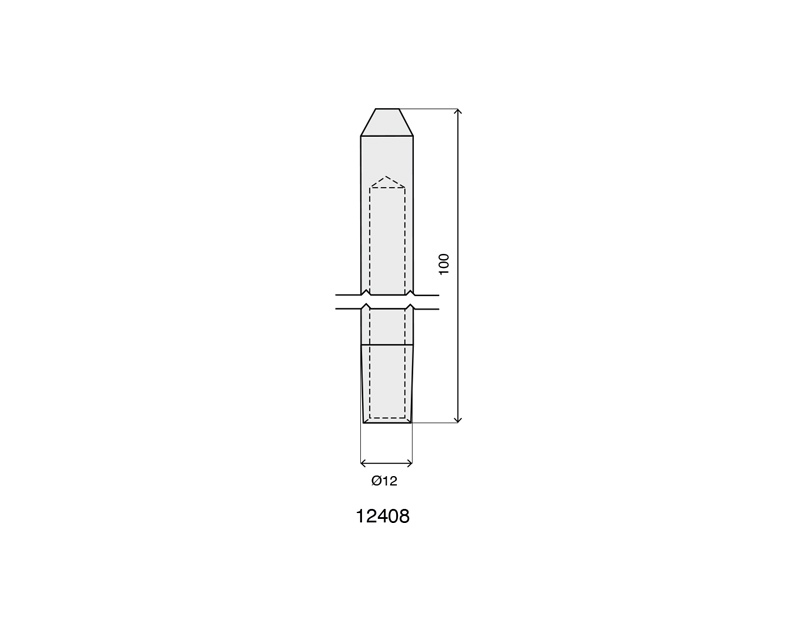

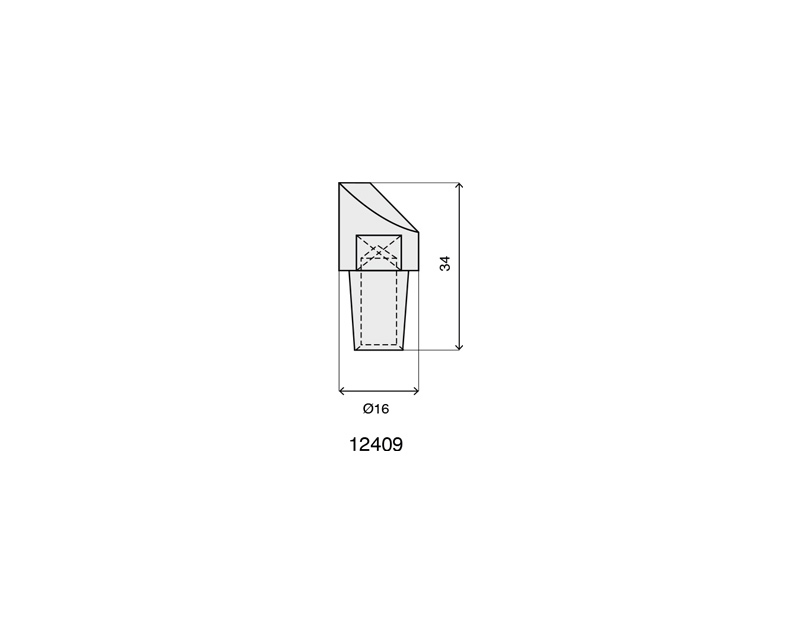

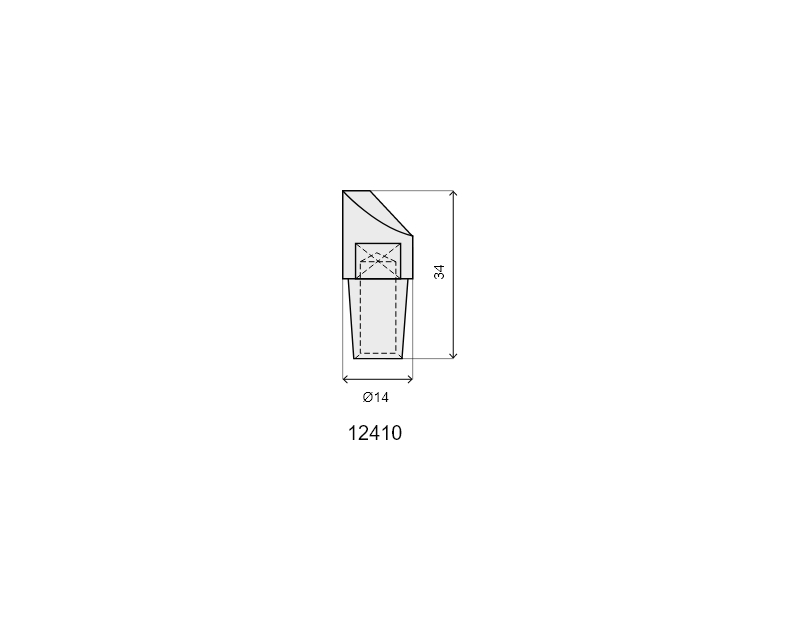

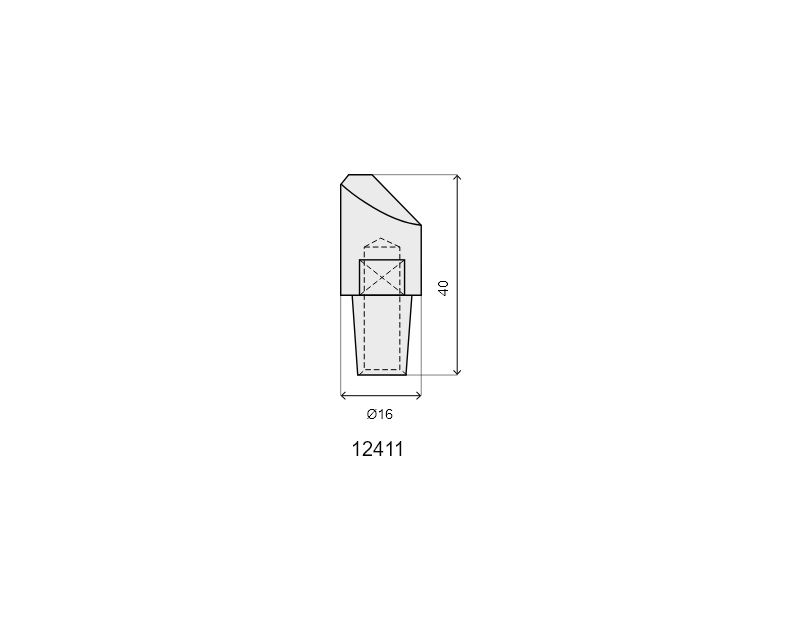

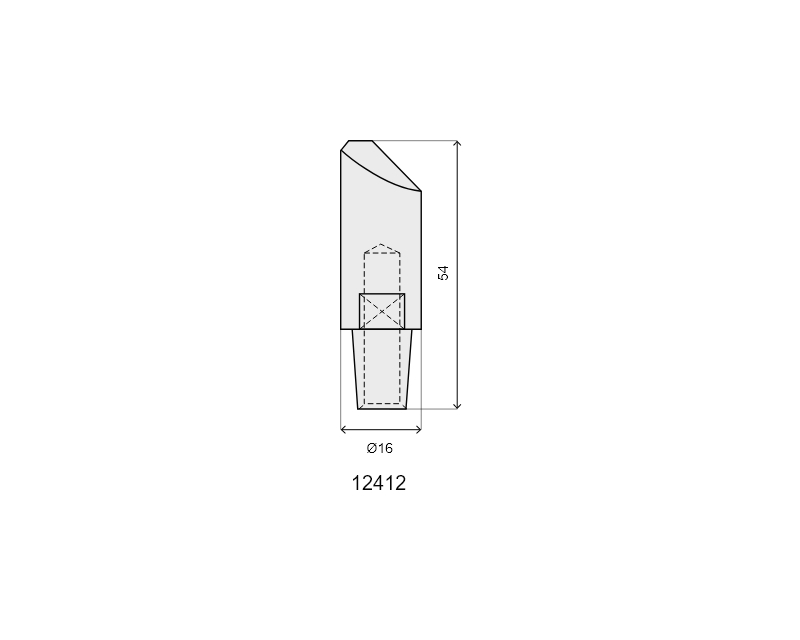

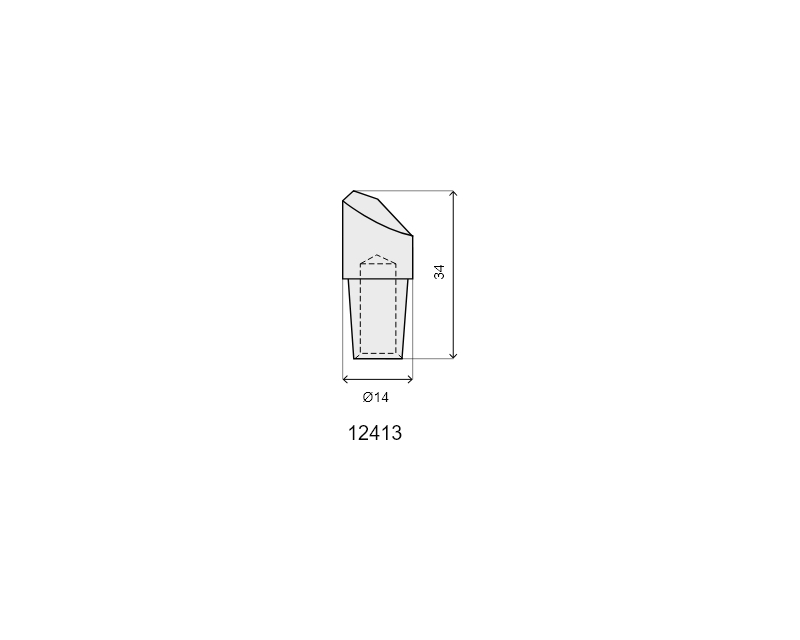

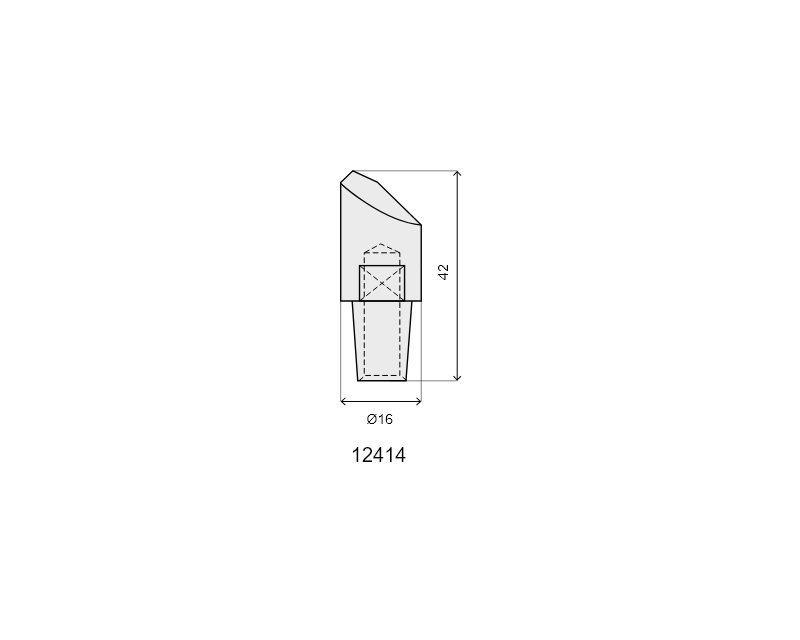

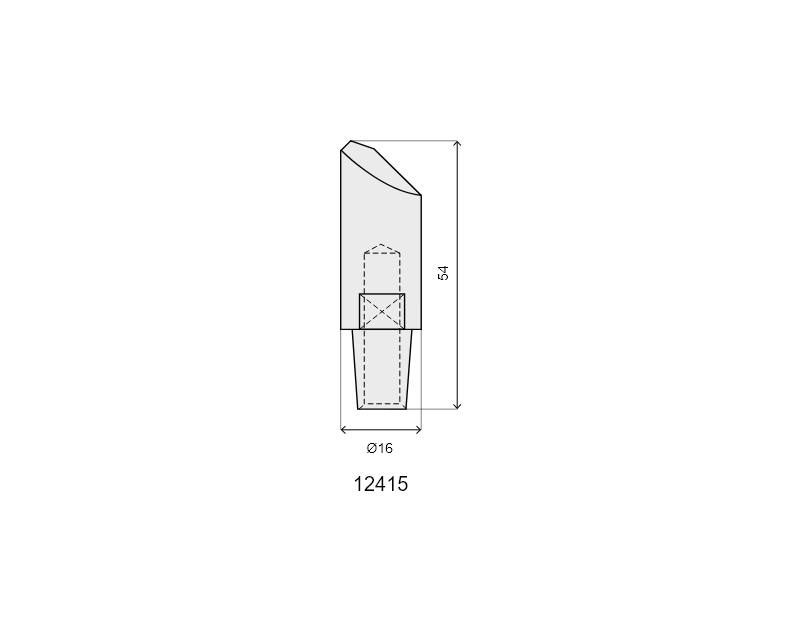

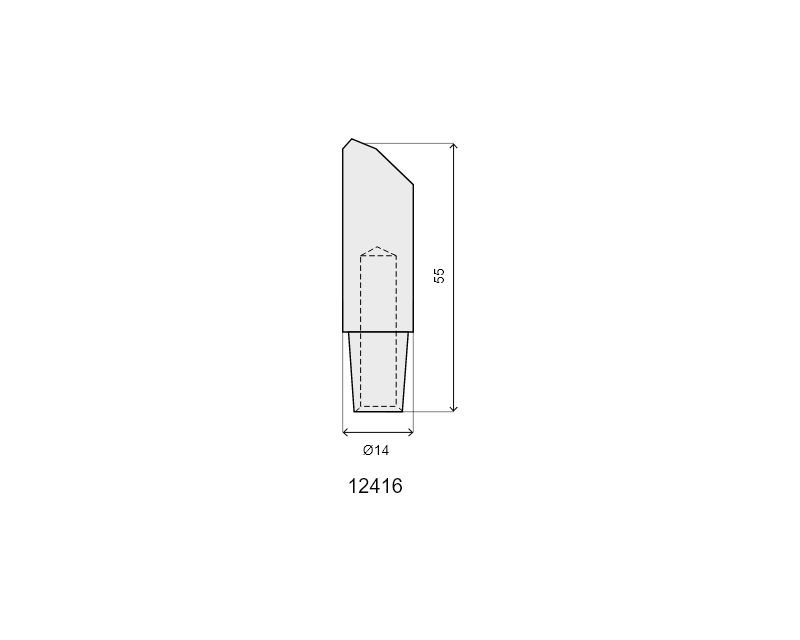

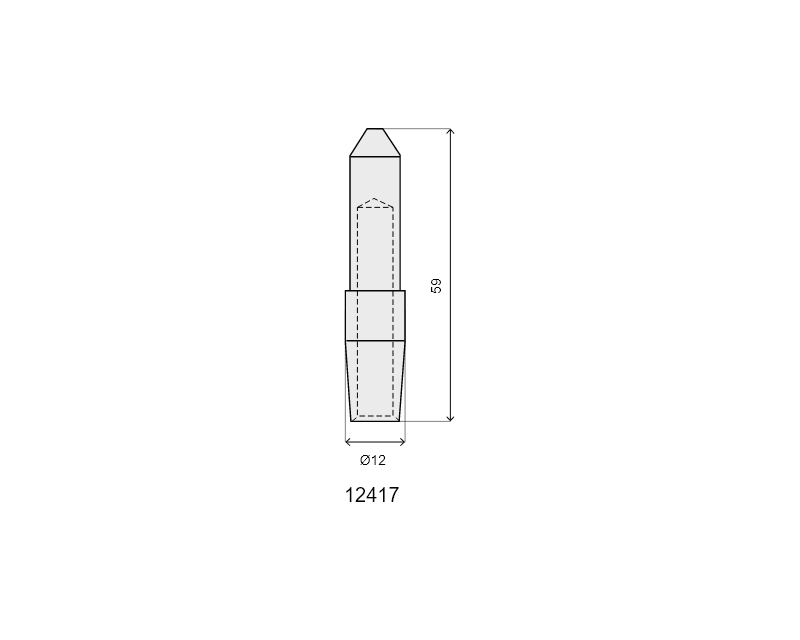

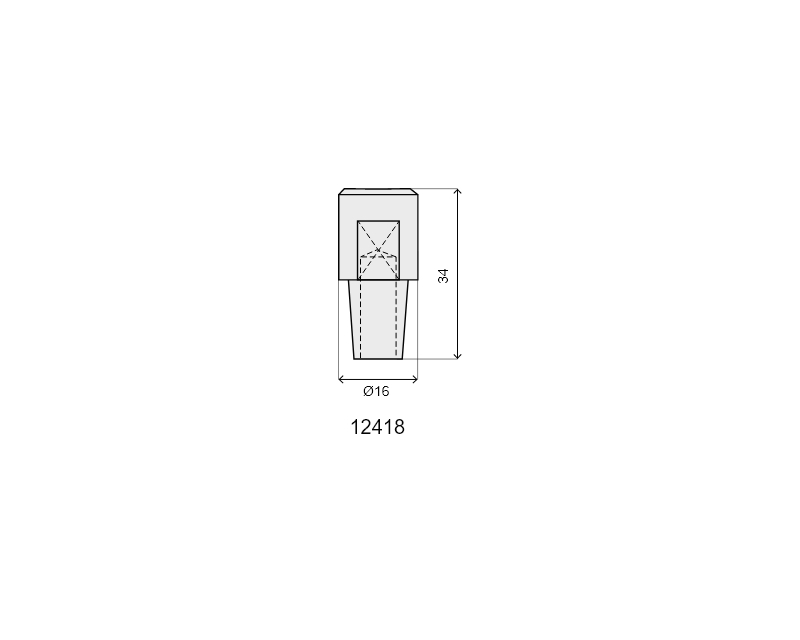

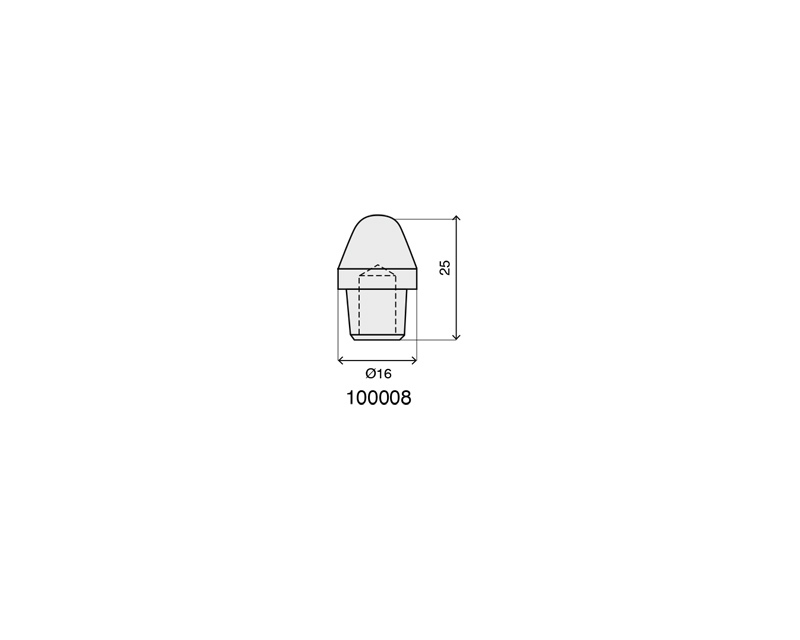

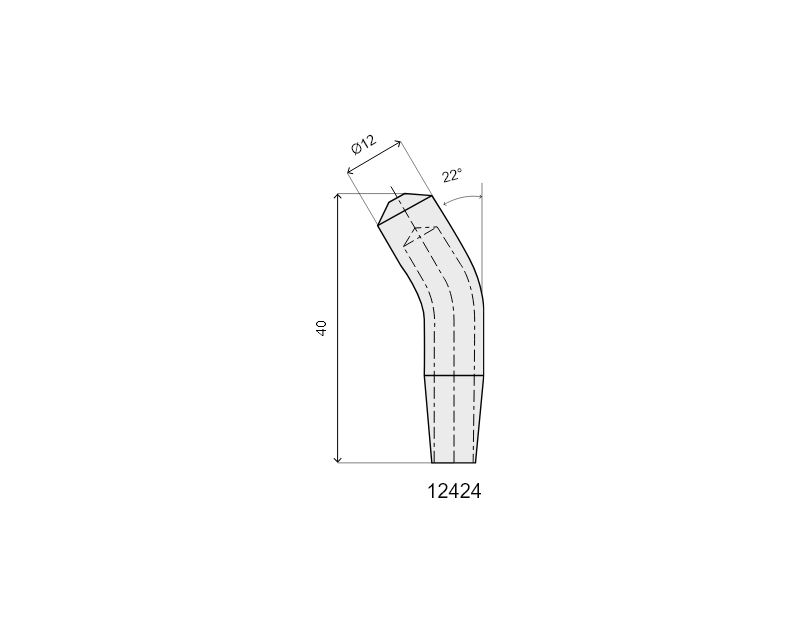

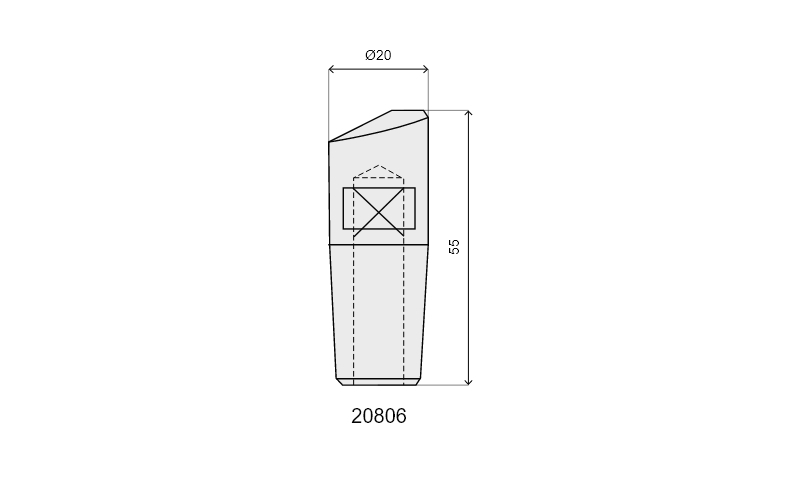

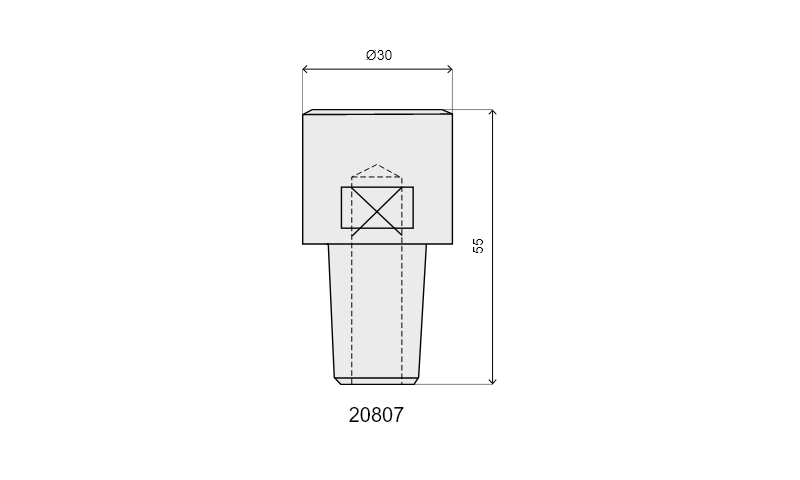

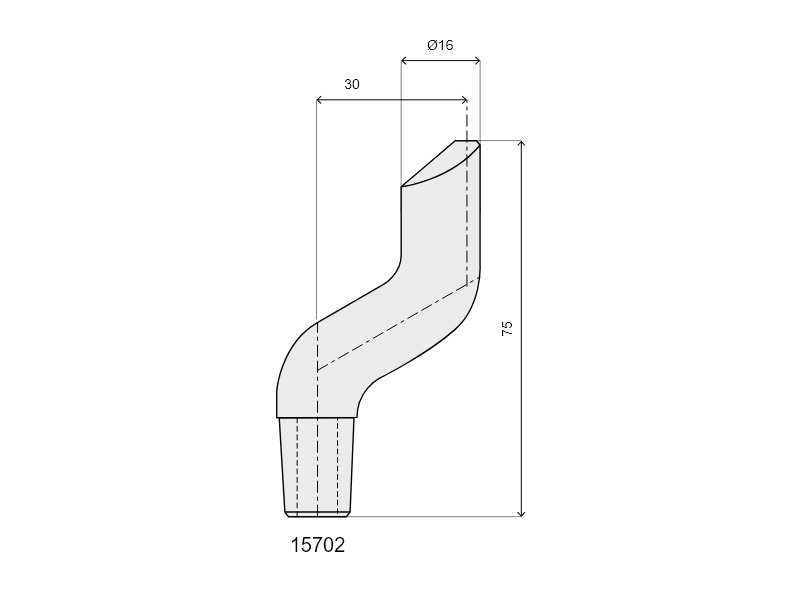

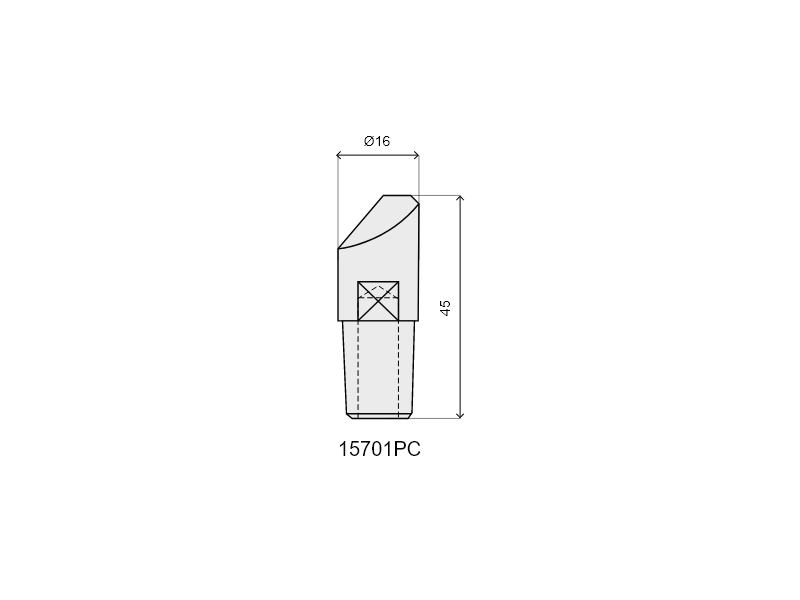

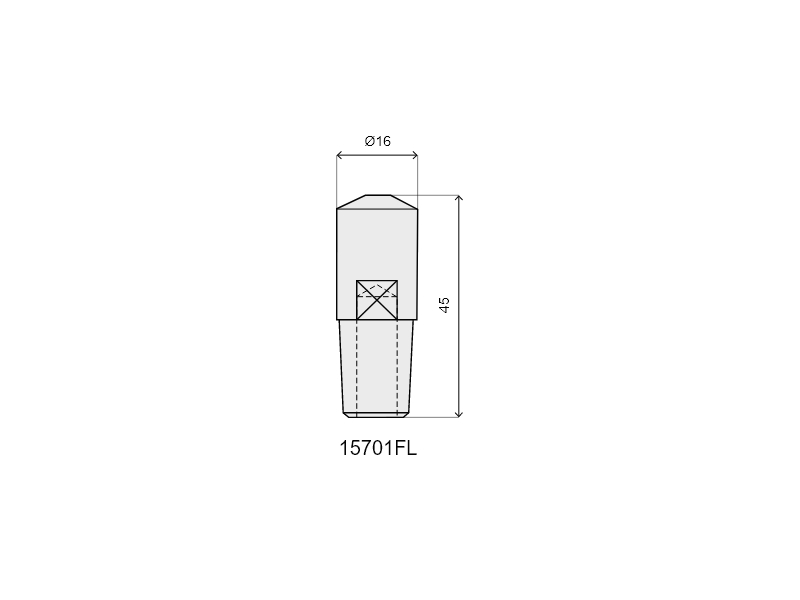

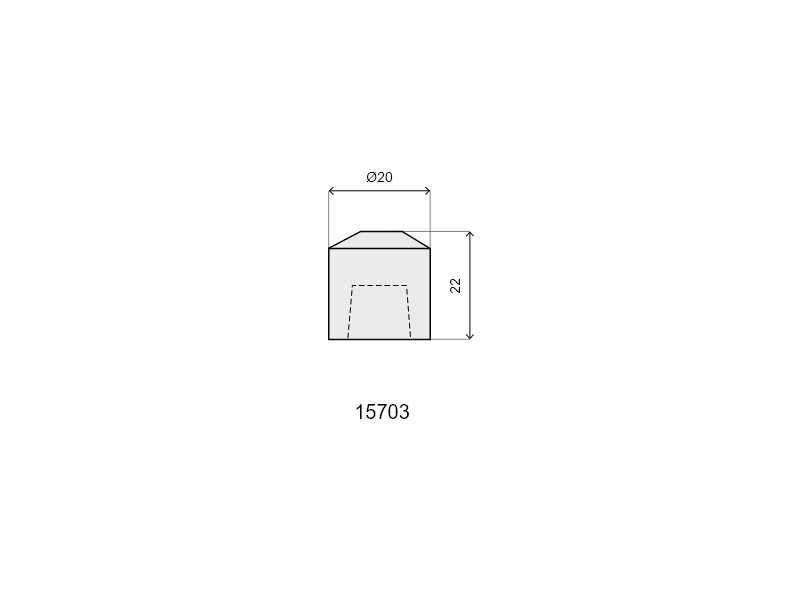

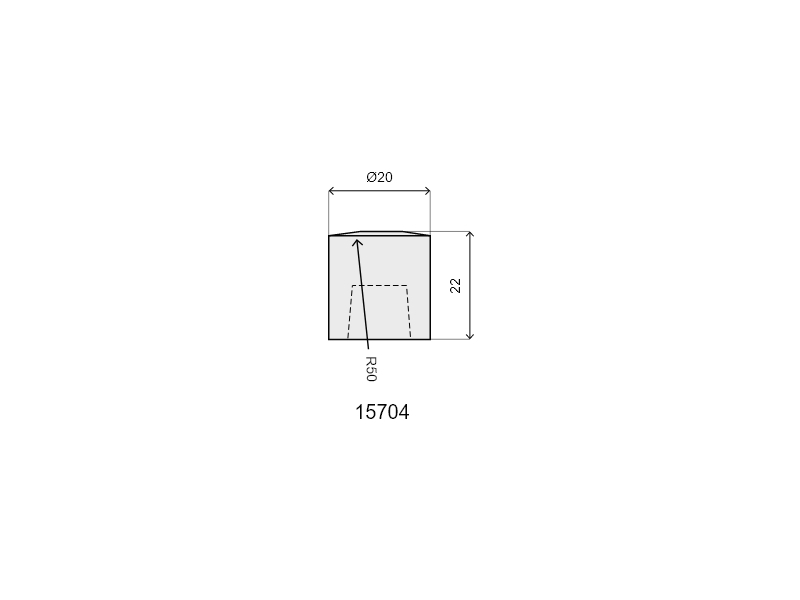

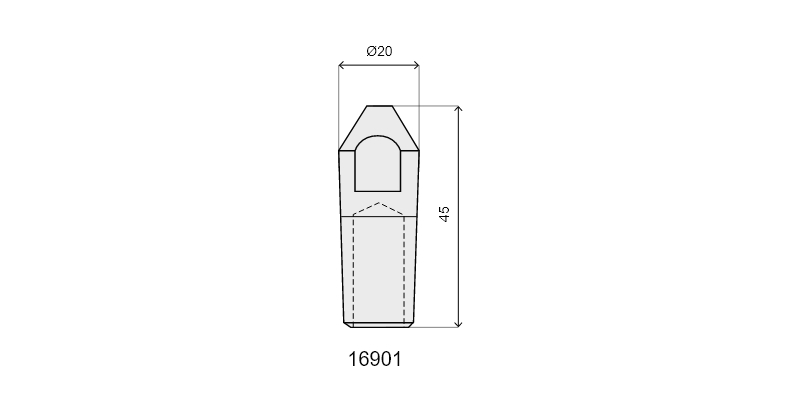

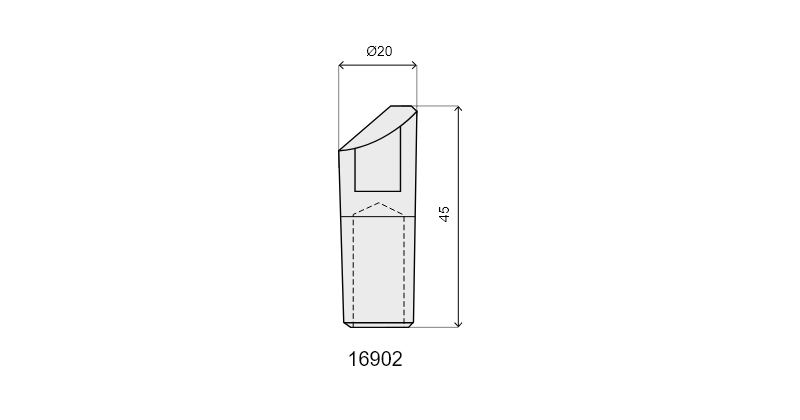

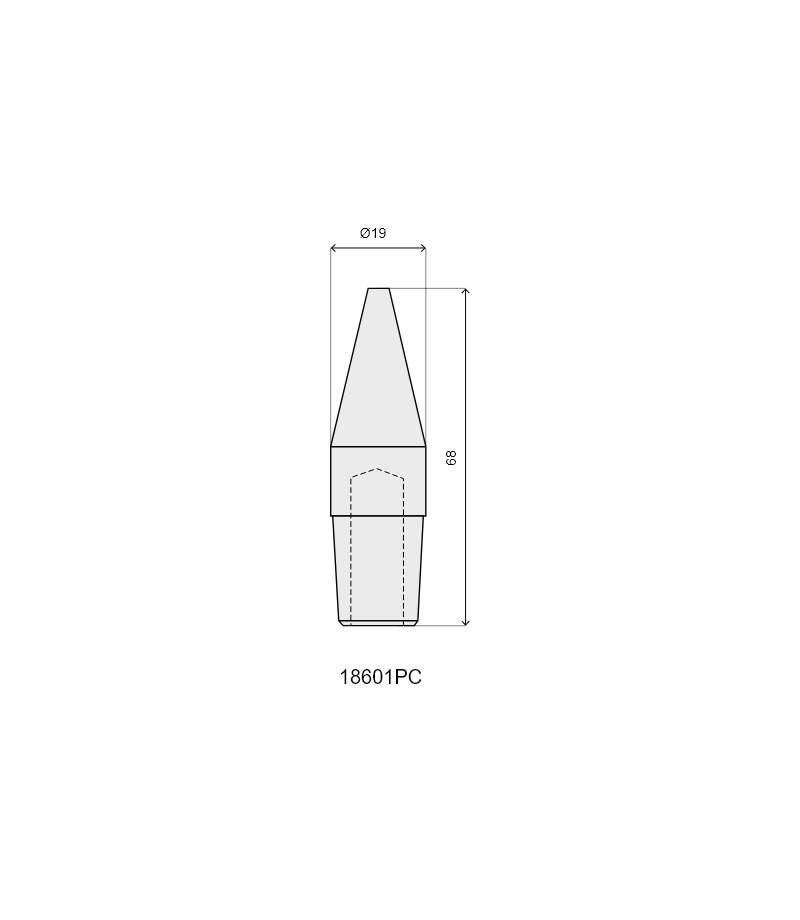

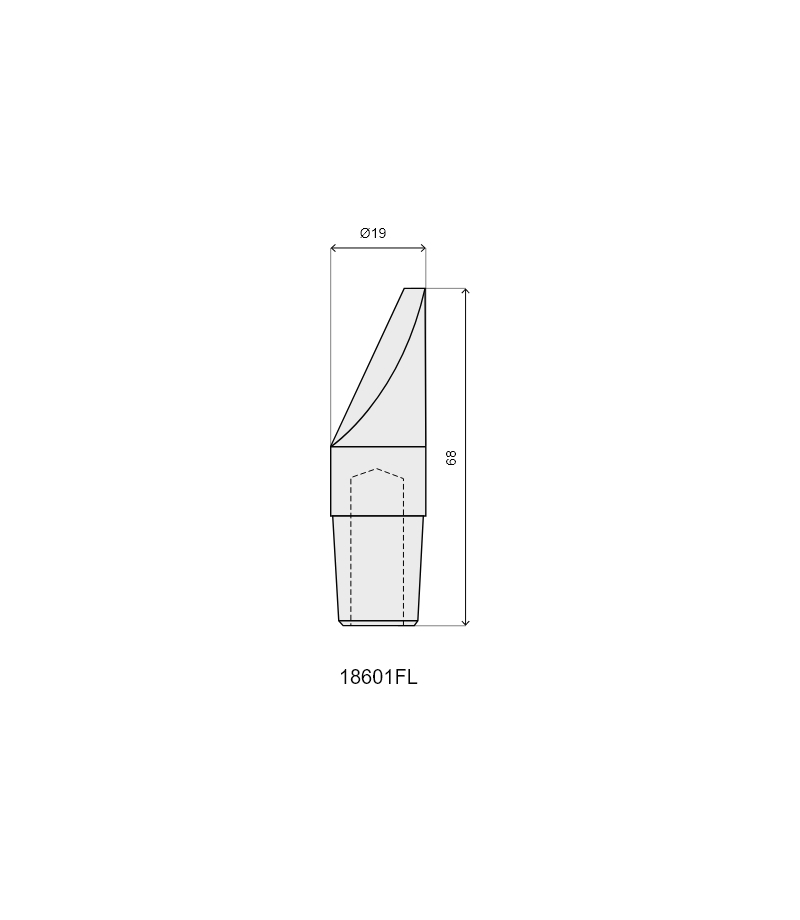

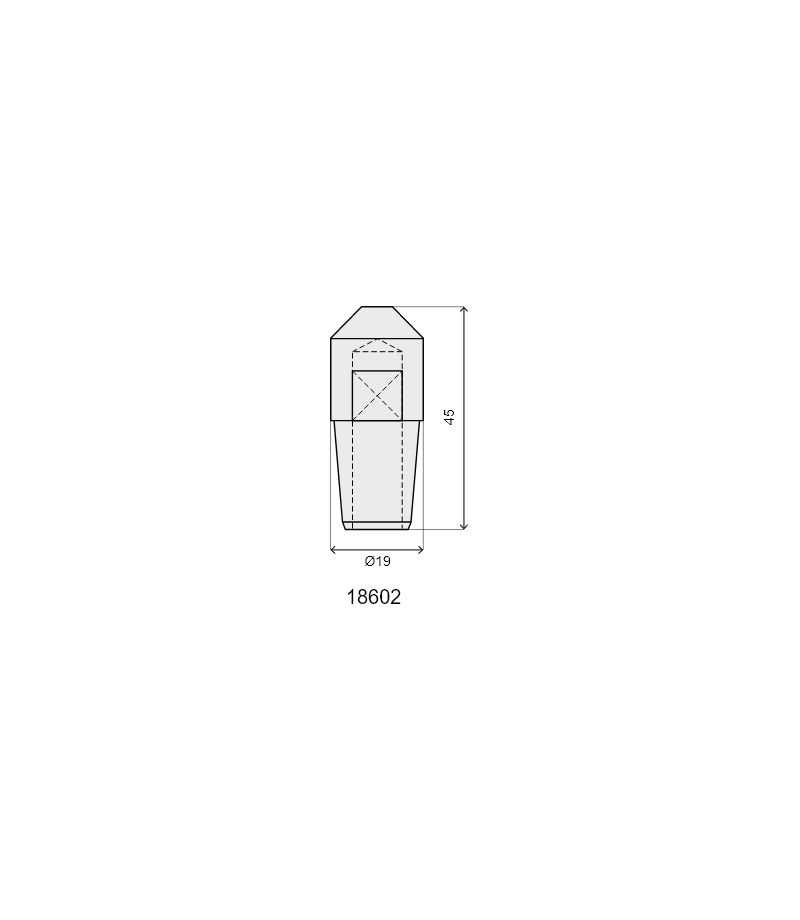

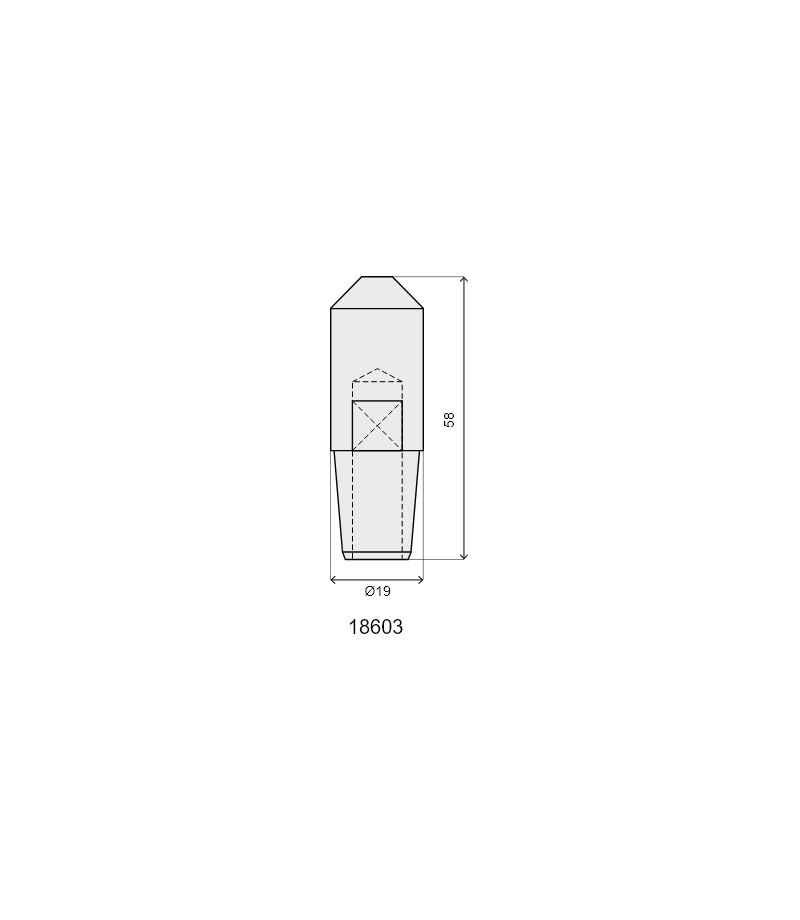

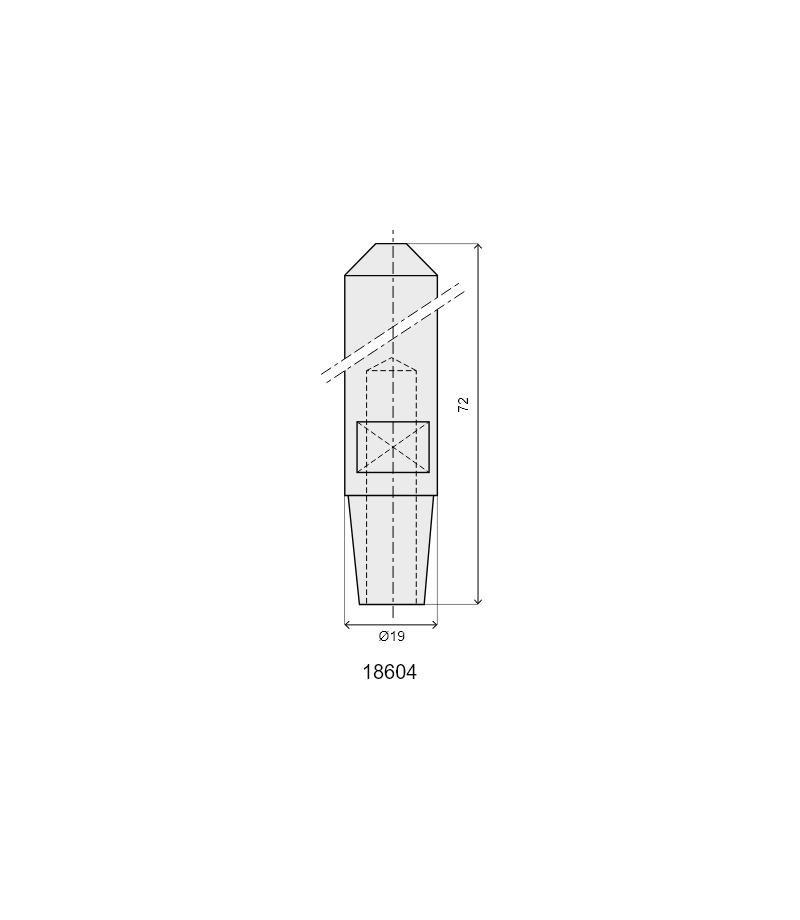

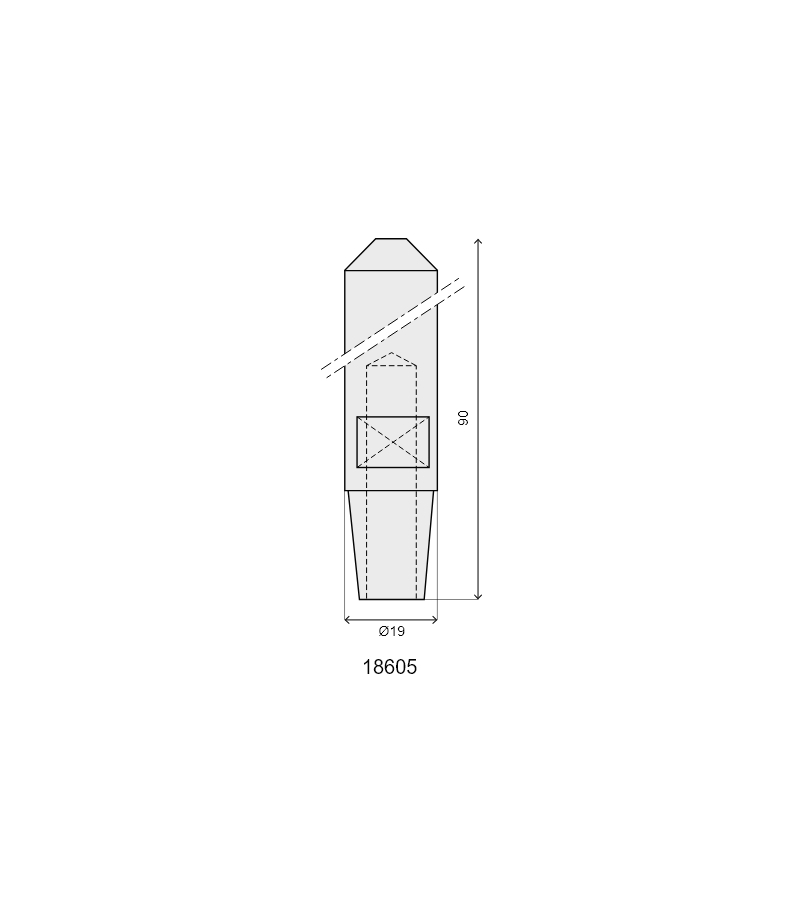

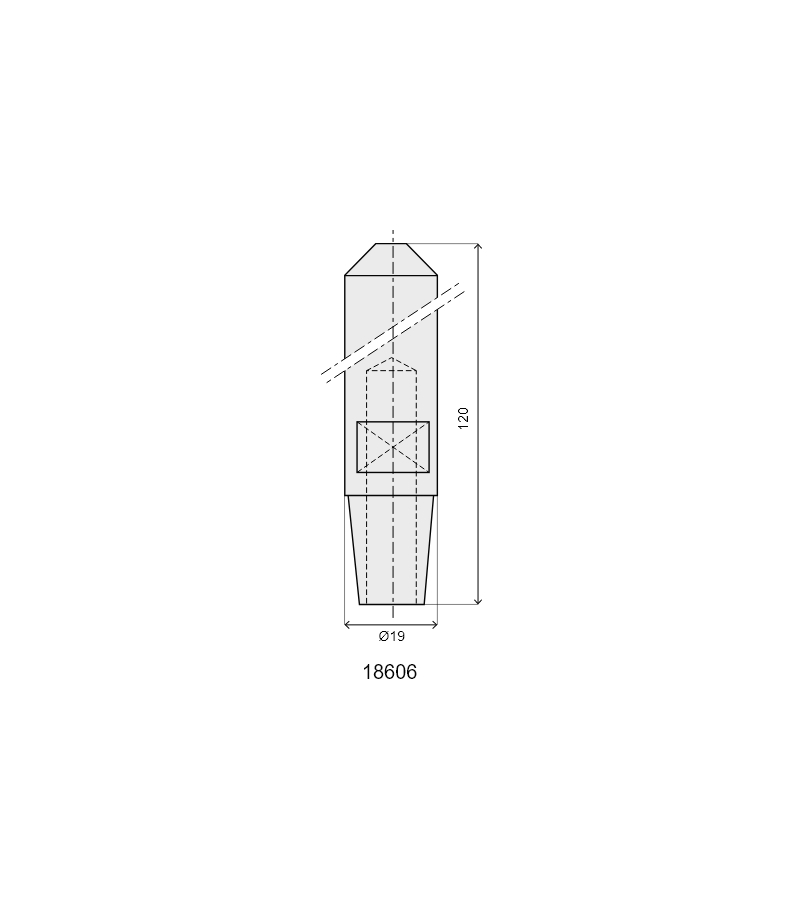

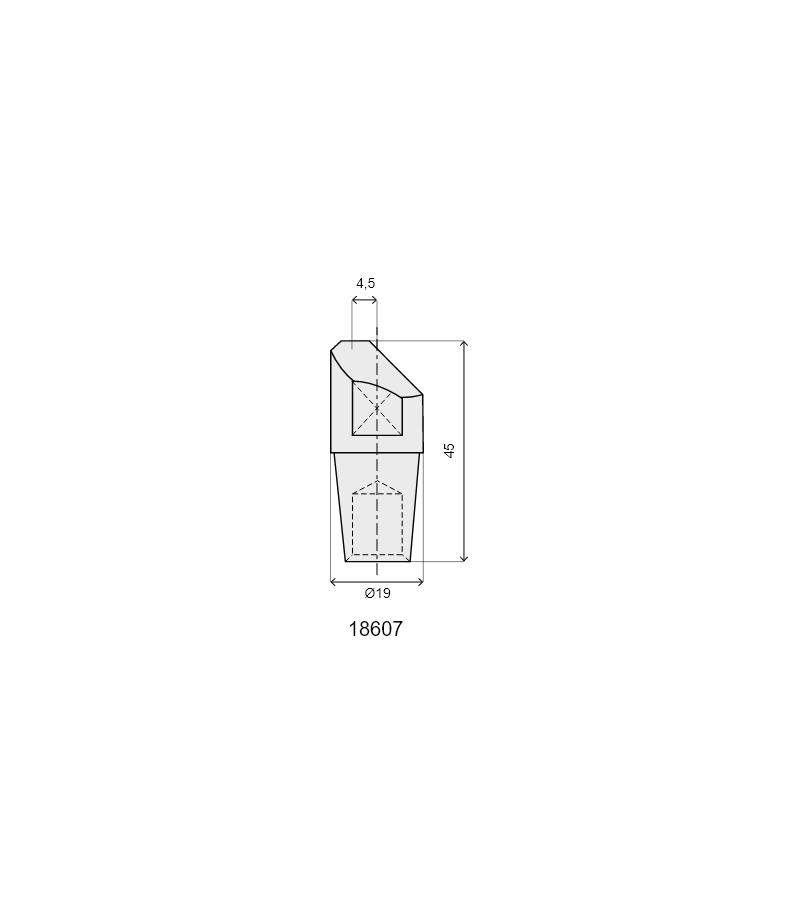

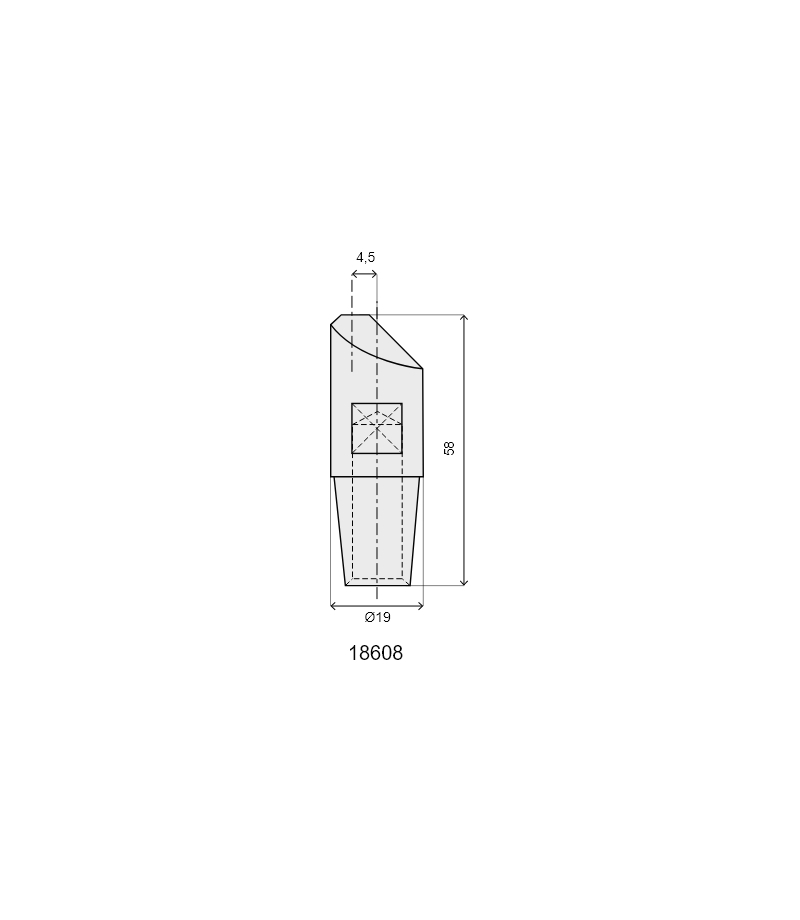

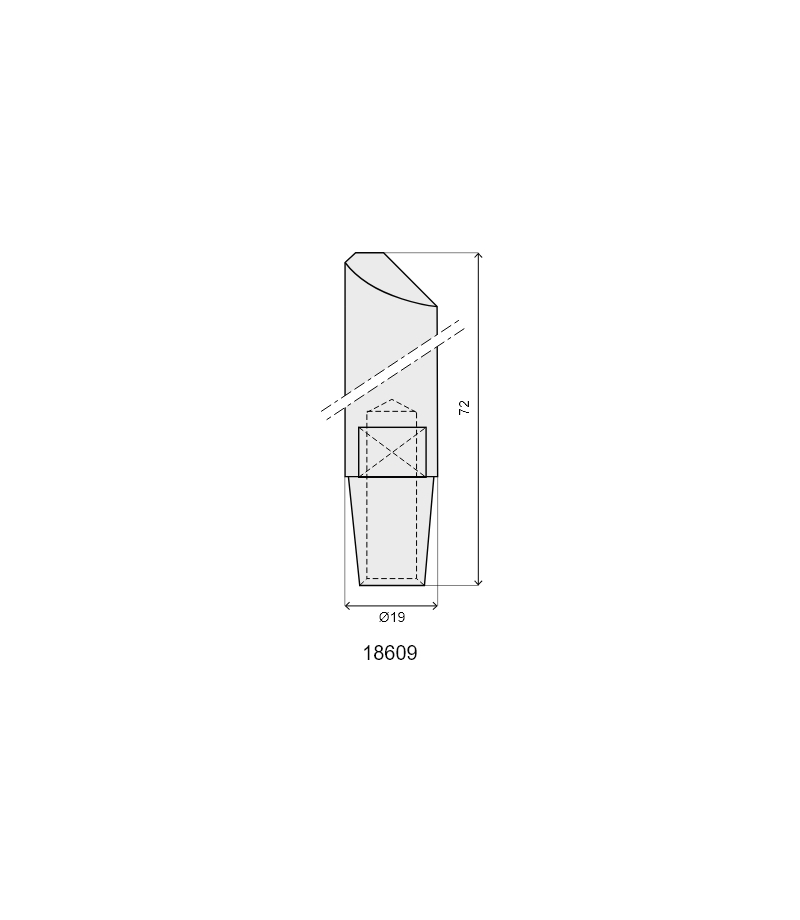

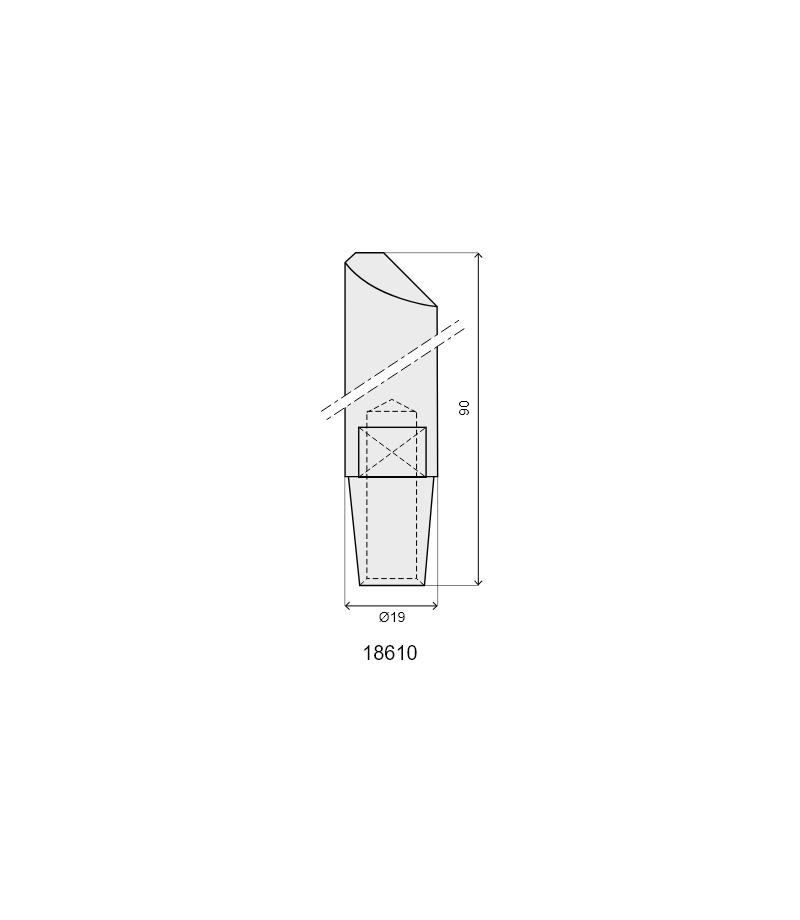

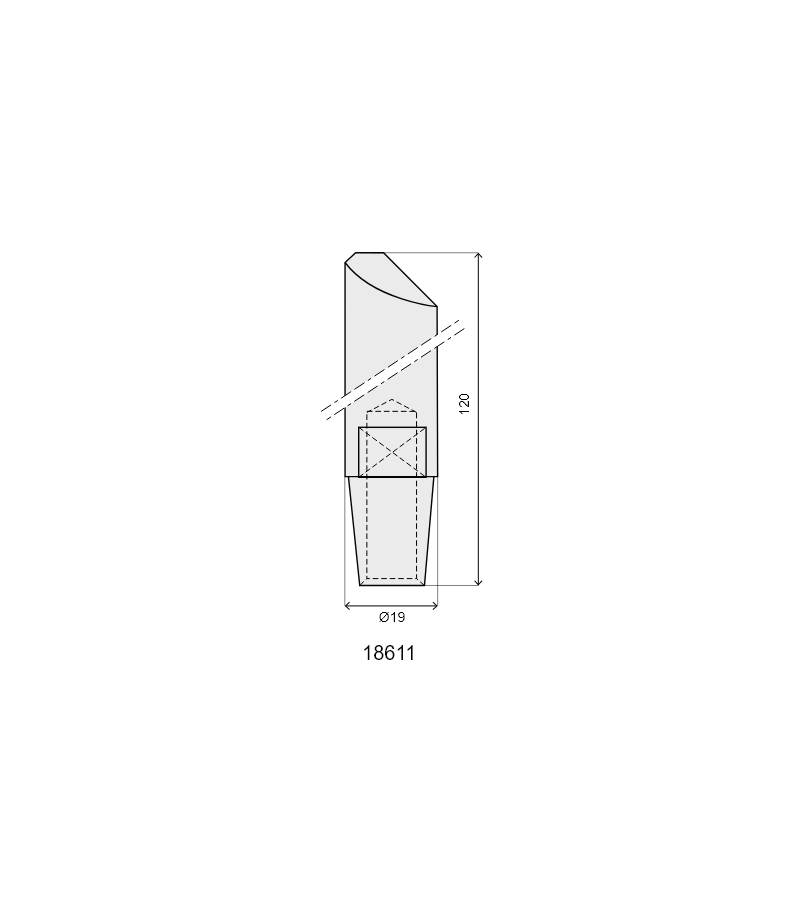

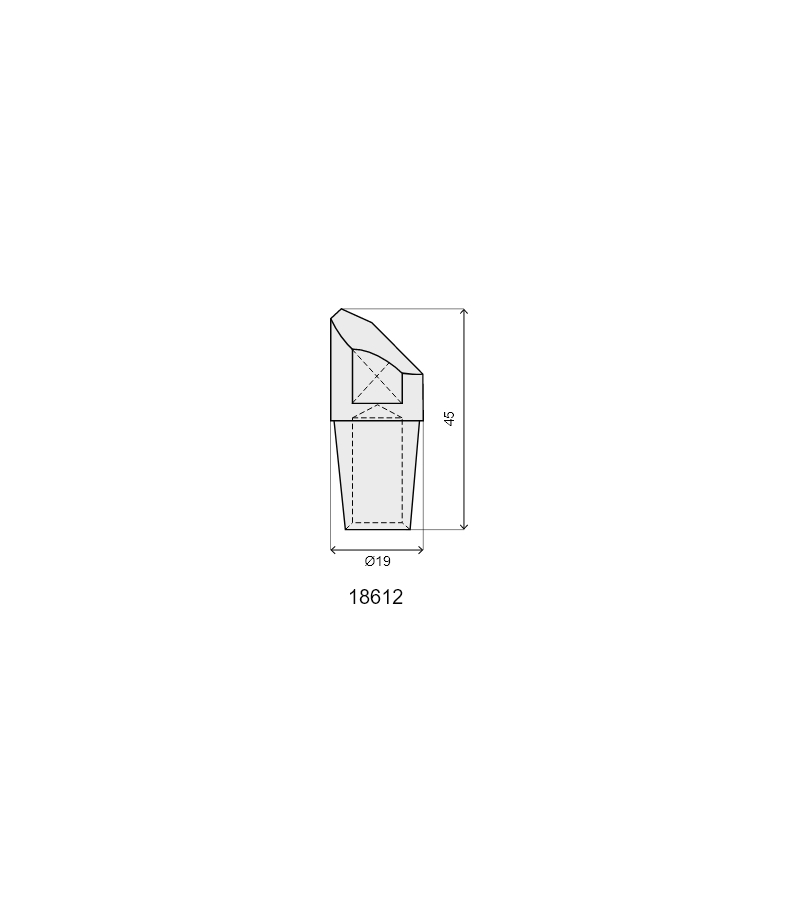

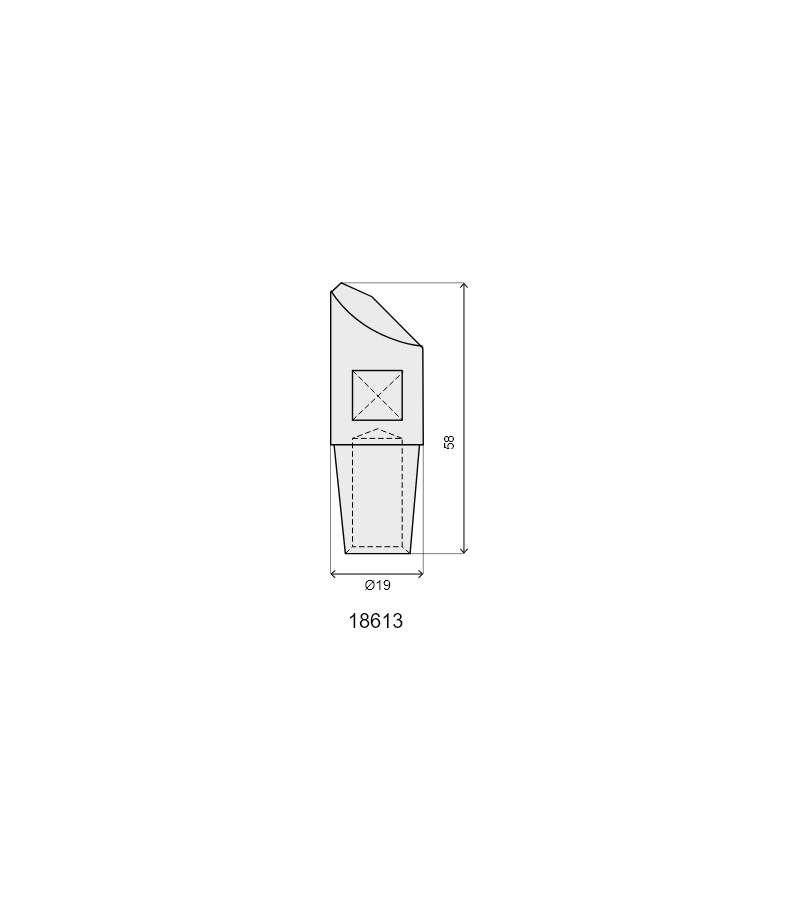

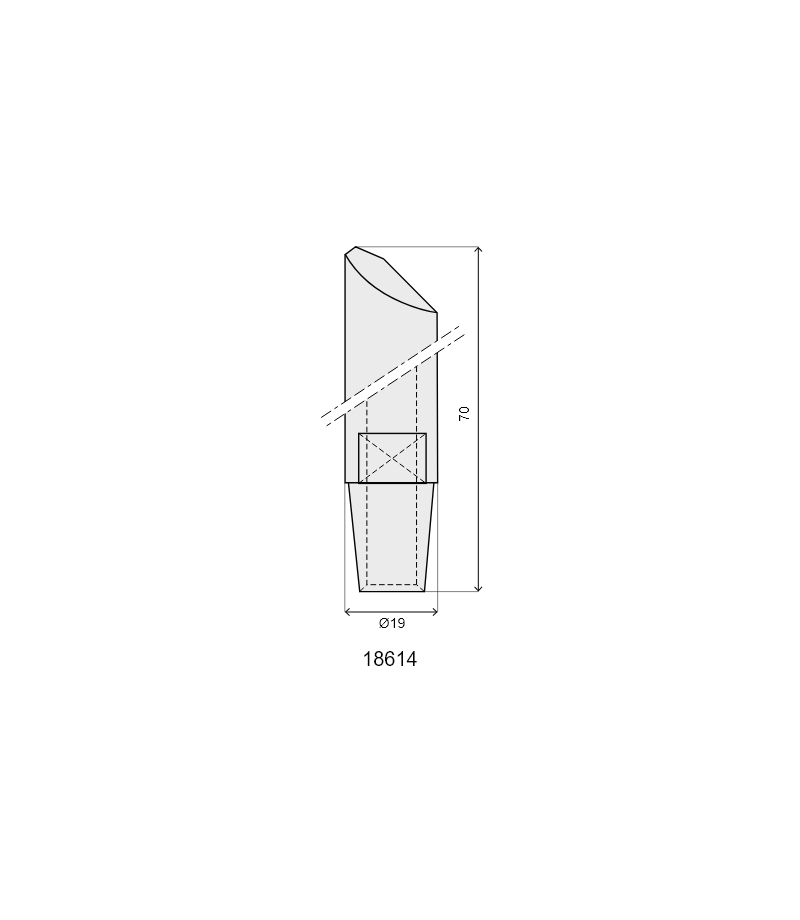

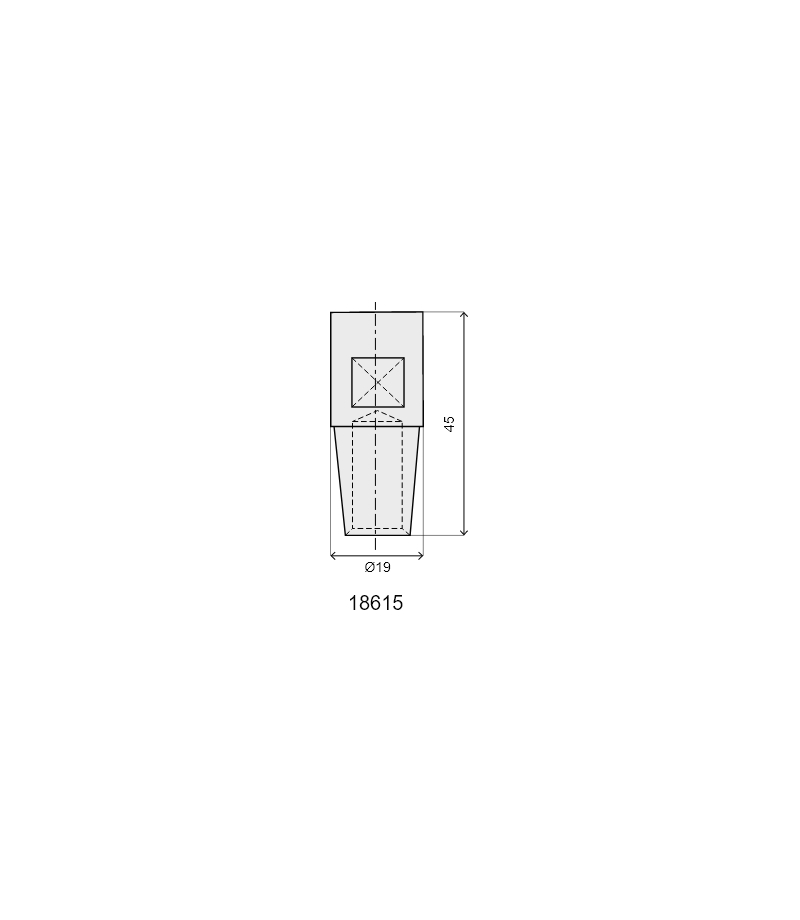

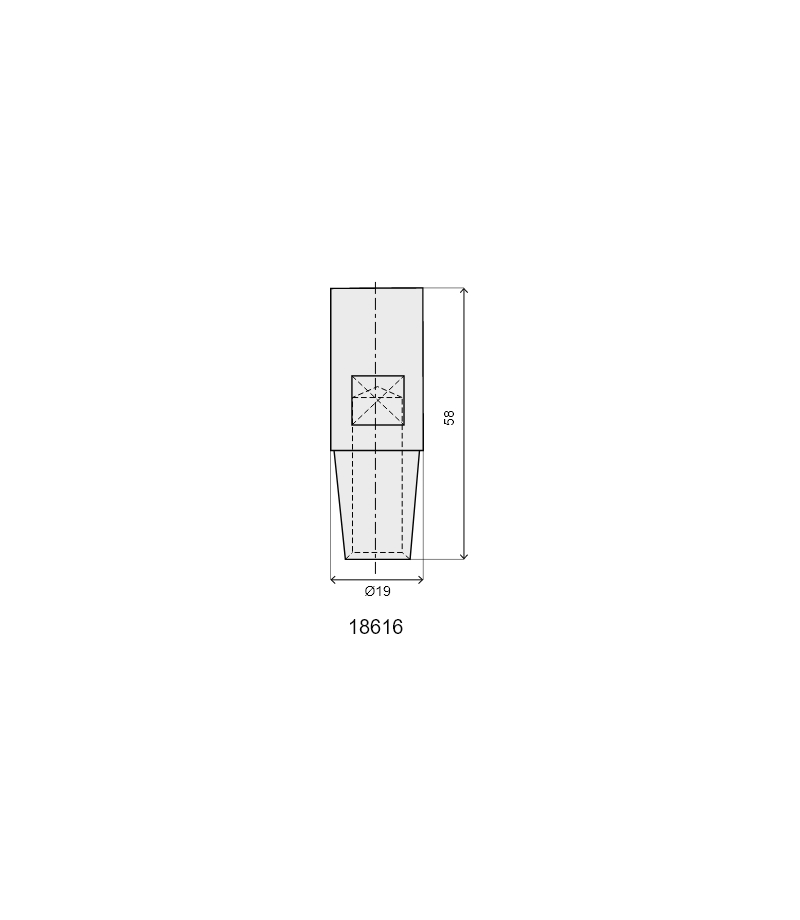

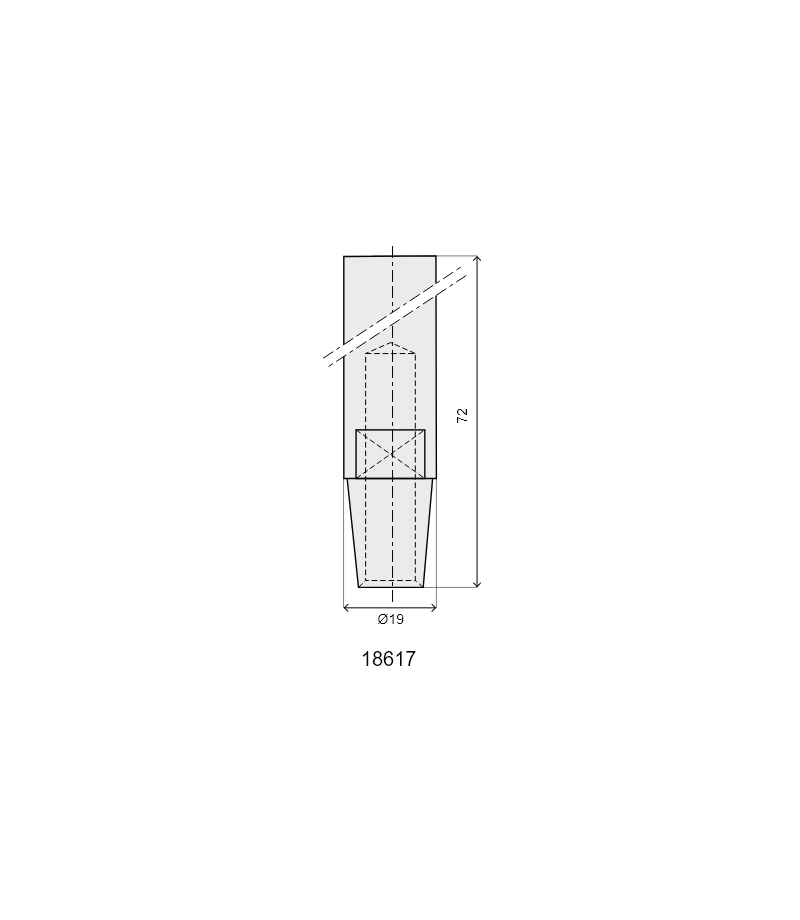

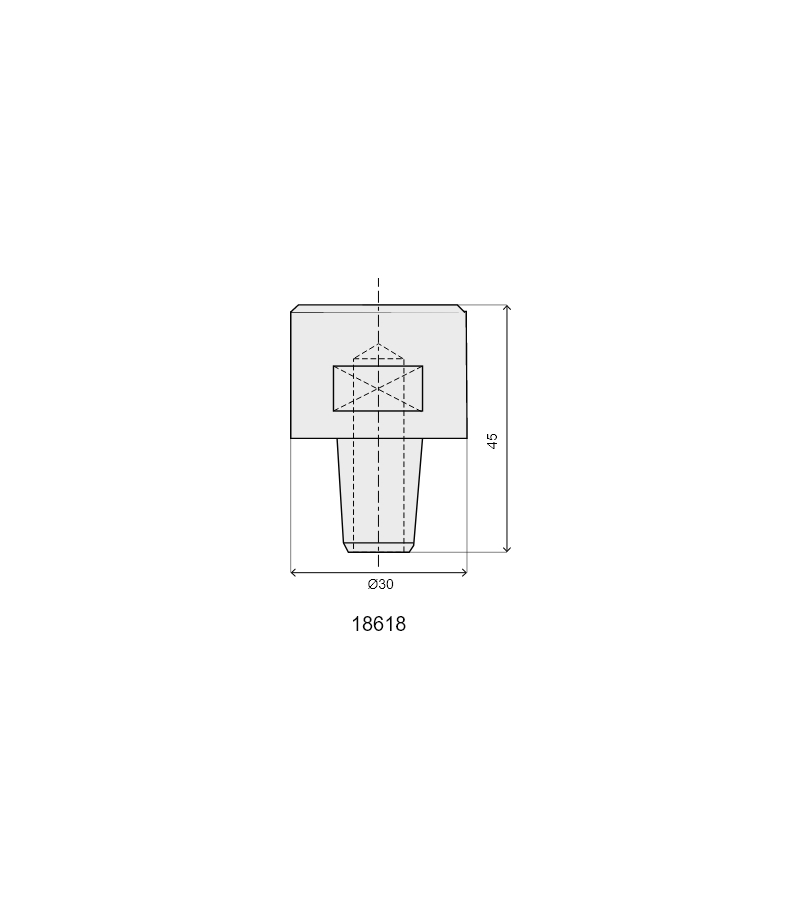

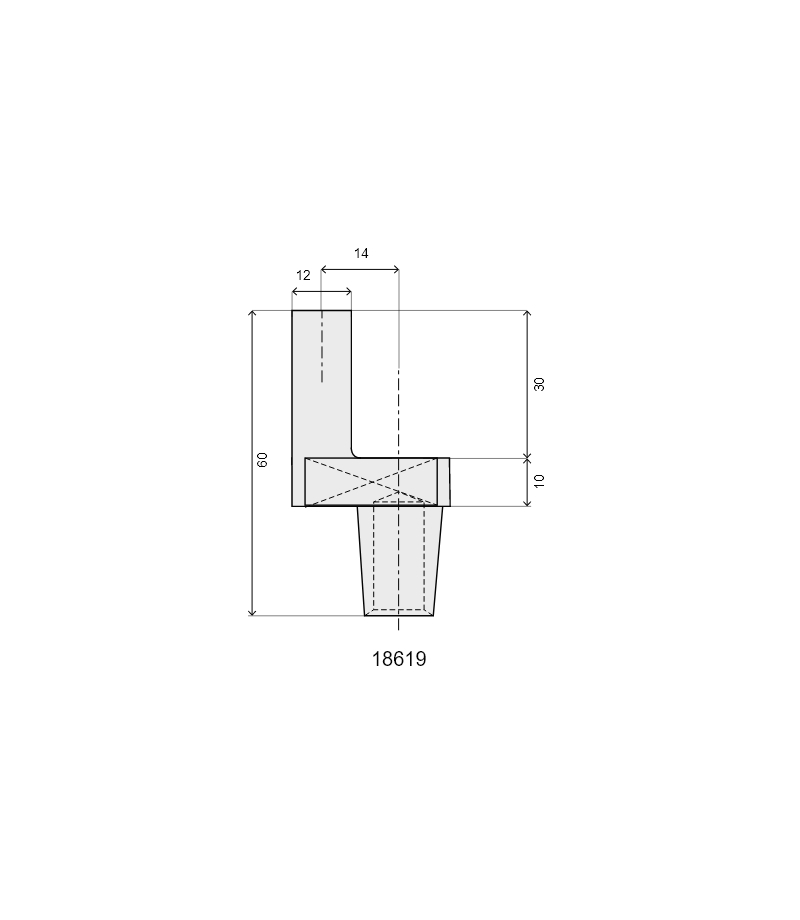

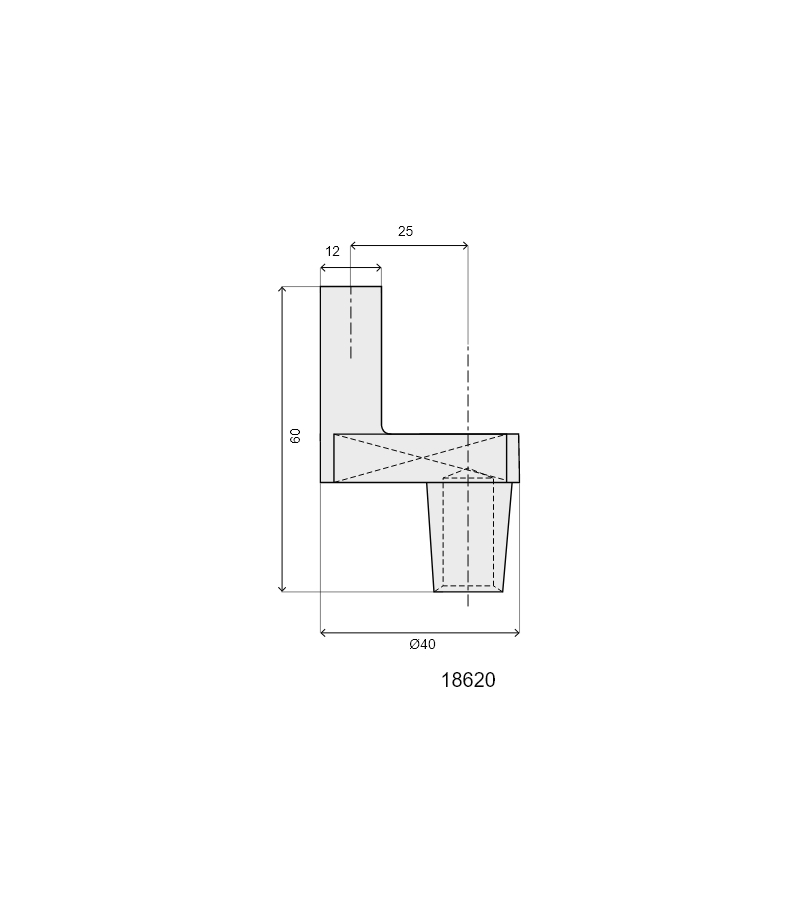

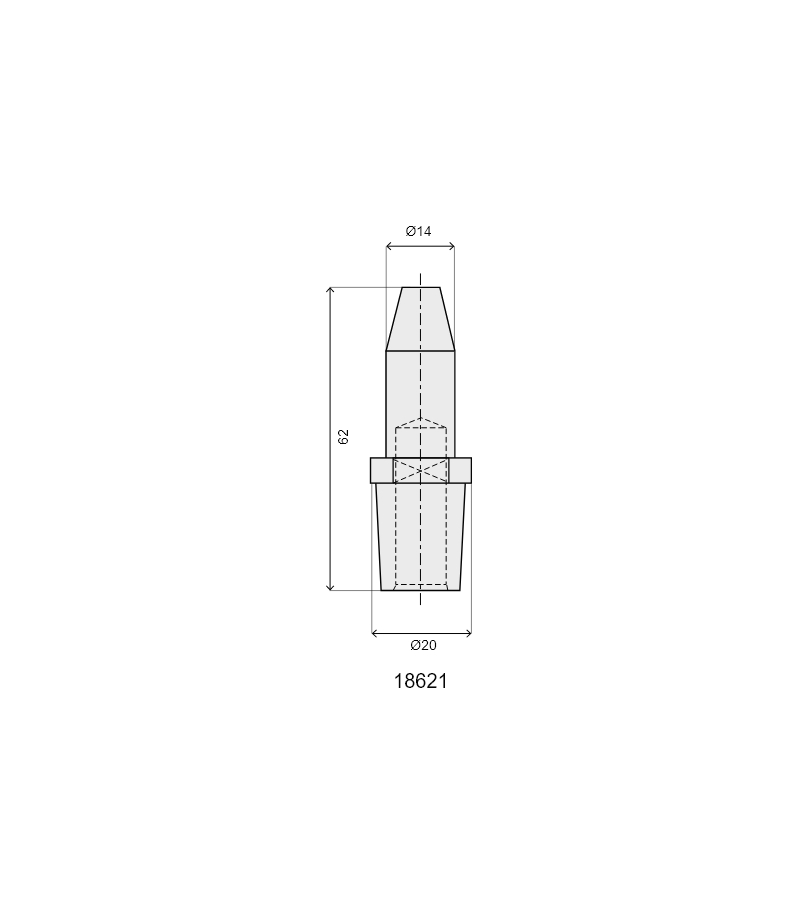

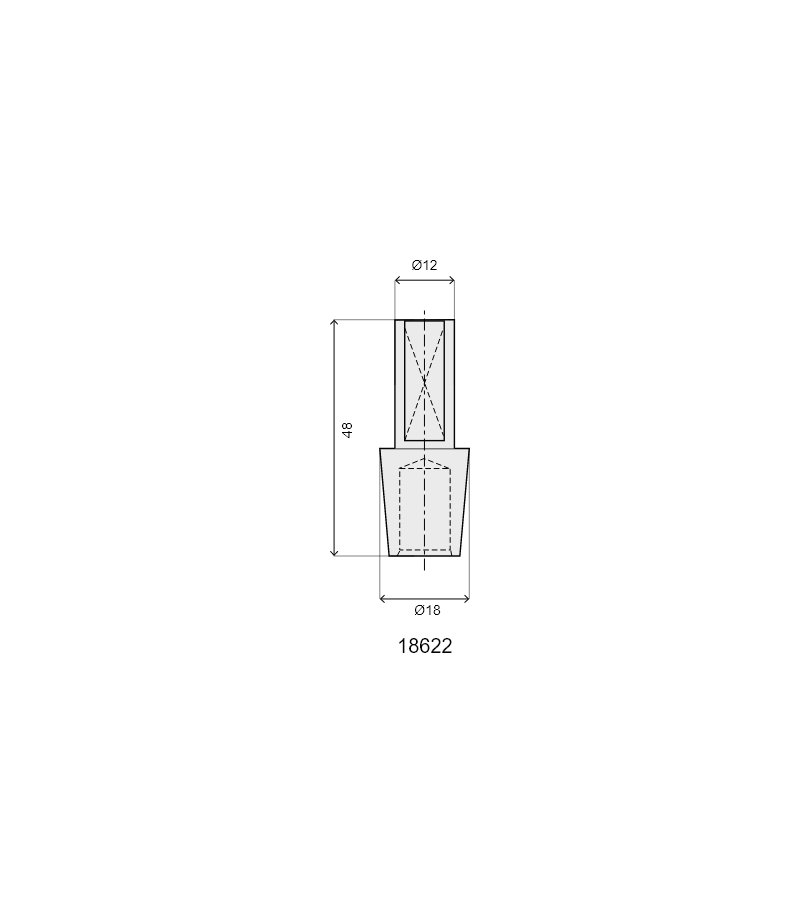

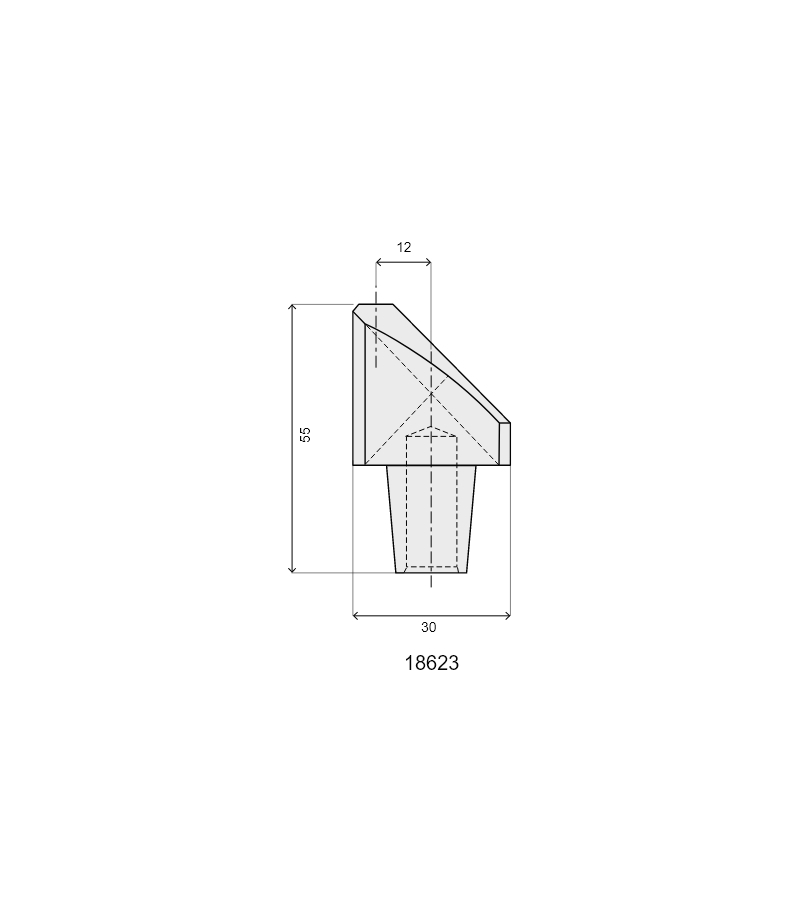

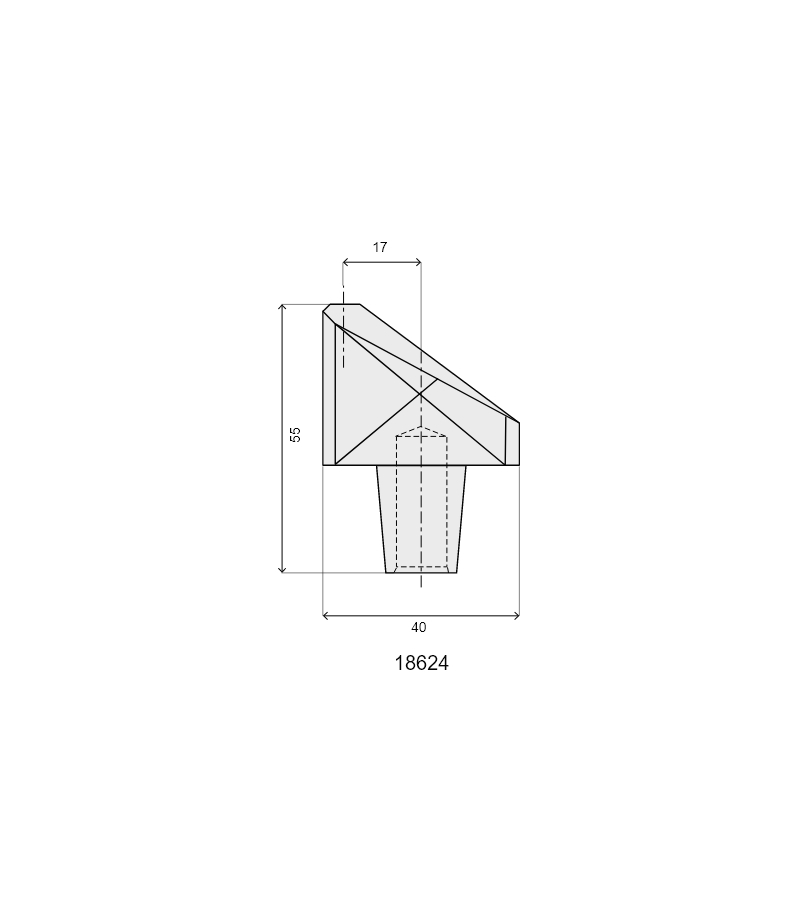

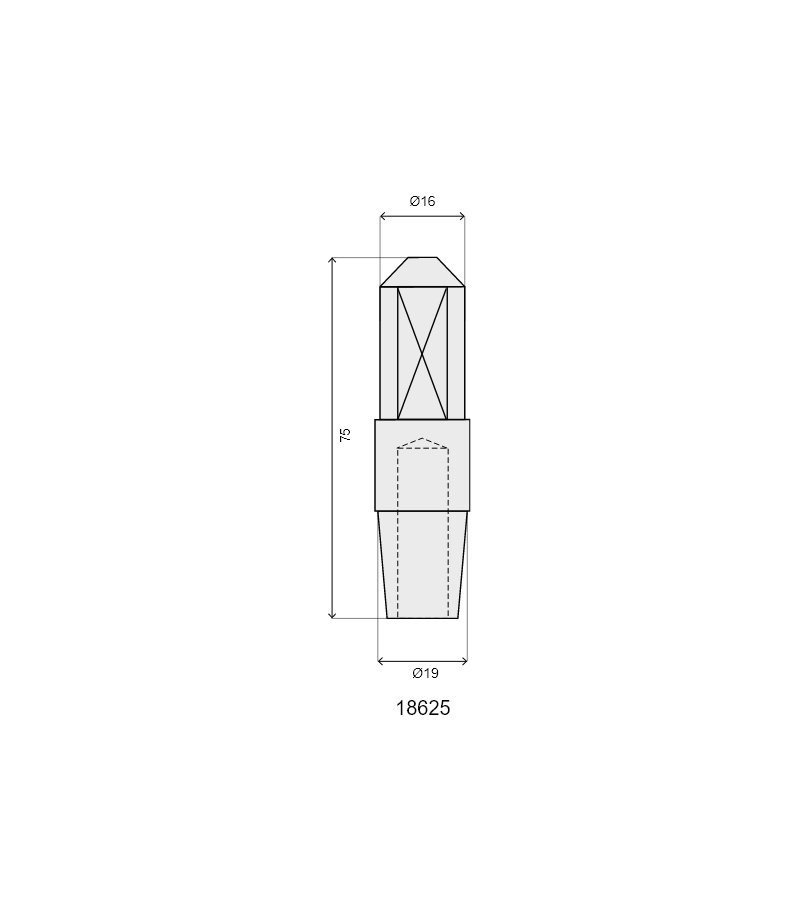

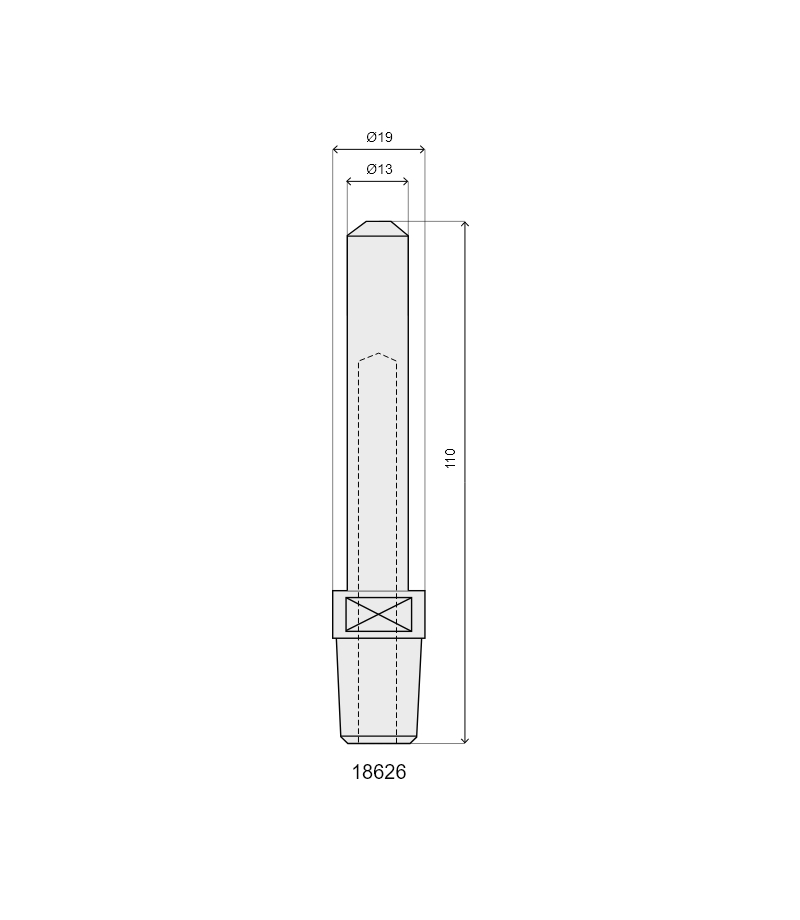

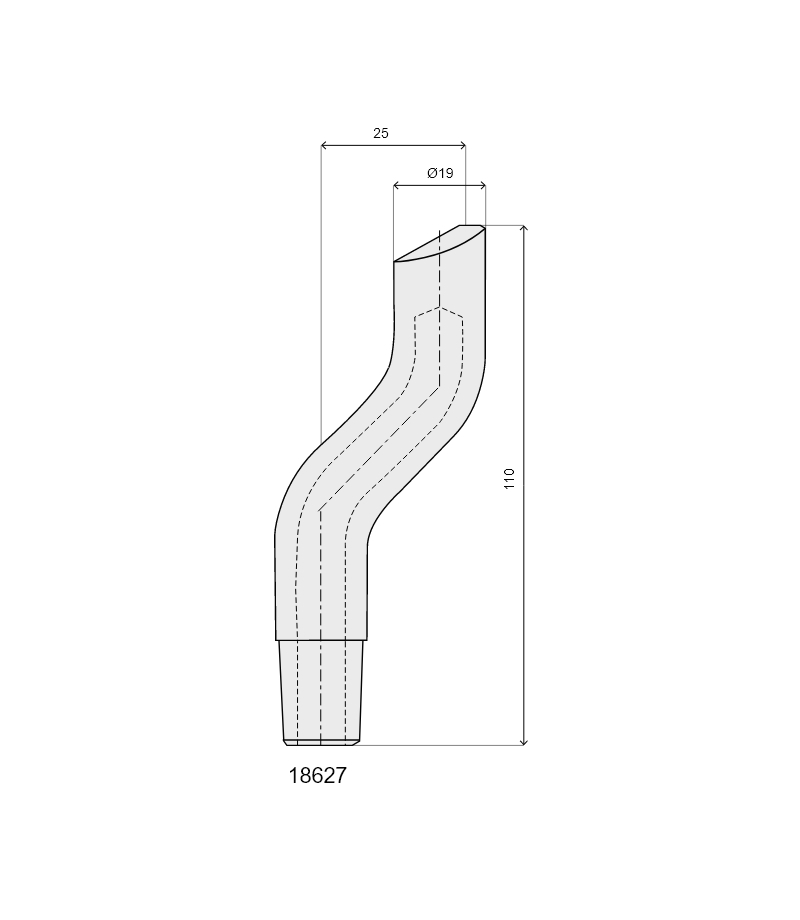

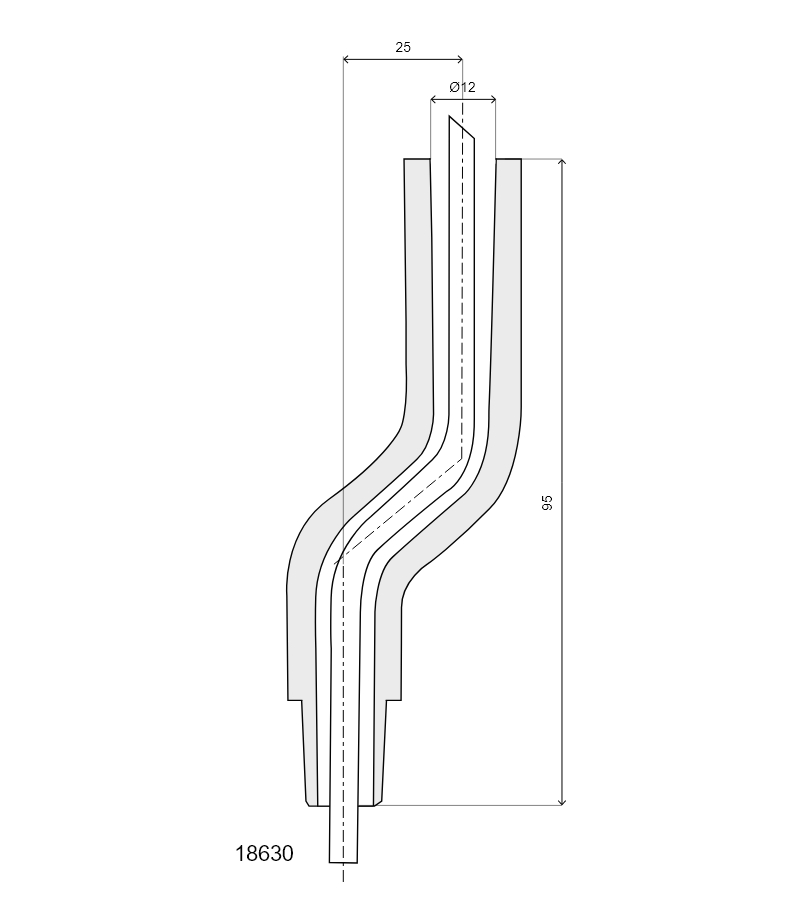

Discover our range of spot welder electrodes

CUSTOM-MADE

IMMEDIATE DELIVERY

Electrodes for all types of taper and dimension

Specific welding needs

Our custom and customisable electrodes are suitable for any welding requirement, from the simplest to the most complex, for example:

For any other requirements, we can provide advice to achieve the ideal result.

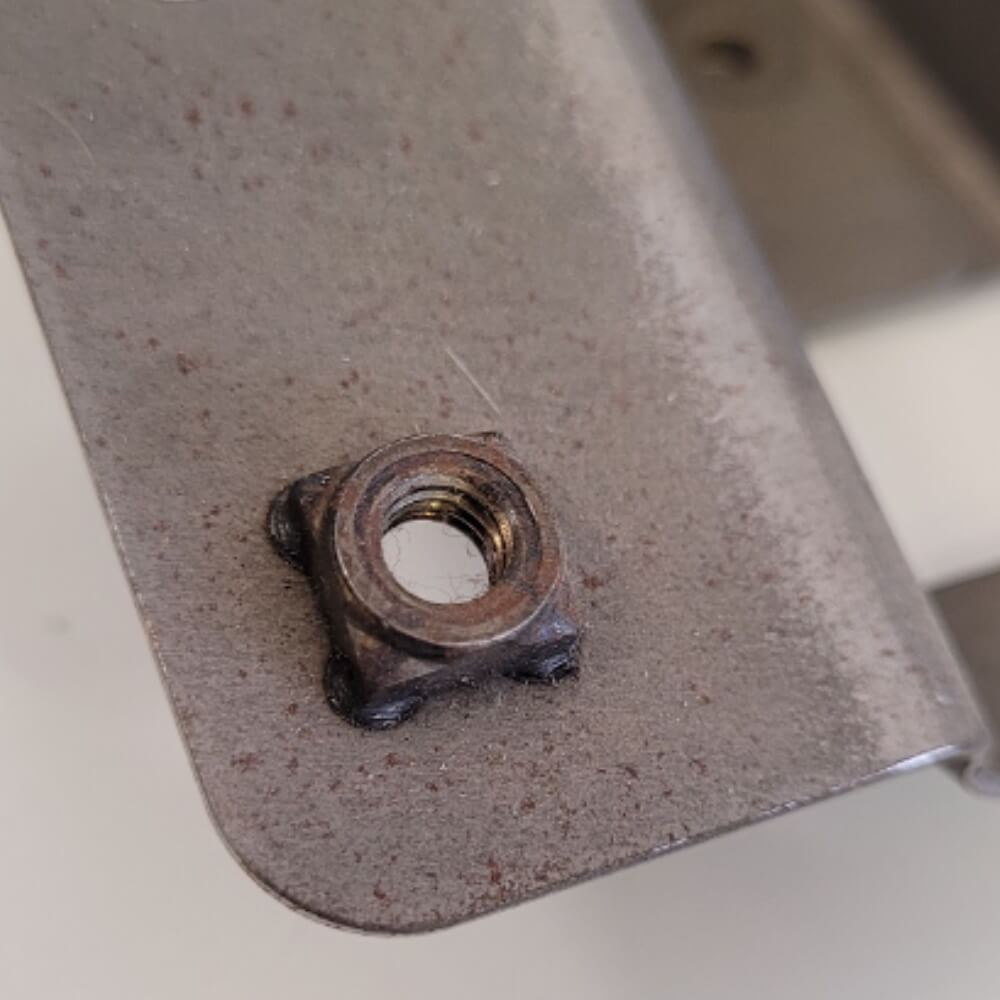

Spot welding: examples of finished products

Why use custom-made electrodes

Sometimes a standard electrode is not enough to achieve the ideal result, many variables must be taken into account:

A customised electrode has many advantages:

In order to achieve a result that conforms to the required standard, we evaluate any samples as a whole, the material and thicknesses to be welded, the number of repetitions per minute, the desired visual effect on the workpiece, the welding processes used and all necessary parts to achieve it.

Why choose Tecsal

01Immediate delivery

02In-house production

03We are suppliers to the industry players

04Large and small quantities

A solution for every need

We can design and produce electrodes that follow special profiles or radii.

Firstly, it is easy to make a mistake in measuring the taper of an electrode. This error can compromise the final result and cause slowdowns in production or invalidate welding processes, preventing consistent quality parameters from being maintained.

Secondly, an incorrect electrode form can cause problems of various natures, from a lack of mechanical strength to the burning of the workpiece, from poor electrode life to more serious consequences such as damage to the machine itself, due to incorrect parameter settings.

Precisely these kinds of wrong choices can shorten the life of the electrode. It can also be an unsuitable mode of use, the machine on which it is mounted, the type of material to be welded that is not optimal. With technical advice, many problems can be solved, so that procedures can be improved, and the most suitable type of electrode can be chosen.

A custom electrode gives the best results for complex shapes, e.g. in the eyewear industry, or for knife handles or special metal furniture. However, there are many sectors that can benefit from our solutions: e.g. electronics, carpentry, household appliances, wire machining, bolting, furniture, electro-medical equipment.